Silica Crucible Temperature Ranges: Top Custom Manufacturers & Suppliers Guide

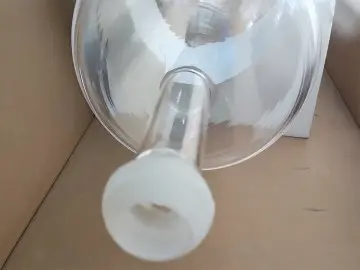

Our high-quality silica crucibles are designed to excel in demanding environments, offering exceptional durability and performance at extreme temperatures. Understanding the Silica Crucible Temperature Range is essential for optimizing your processes. As a leading manufacturer, we prioritize precision and quality, catering to the rigorous needs of metallurgy and ceramics. Our silica crucibles provide reliable solutions for both professionals and businesses, ensuring the highest standards in your applications.Effective Ways To Silica Crucible Temperature Range Industry Leaders Industry Giant

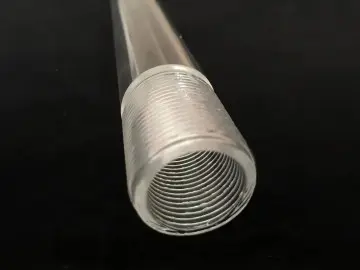

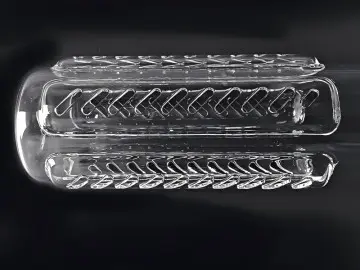

In the world of high-temperature applications, understanding the silica crucible temperature range is essential for industries that rely on precise and reliable material performance. Silica crucibles are widely used for melting and testing metals, glass production, and various laboratory processes, making their thermal properties crucial for effective operation. Industry leaders recognize that using high-quality silica crucibles can enhance efficiency, reduce material loss, and optimize production processes. Selecting the right silica crucible involves understanding its temperature tolerance, typically ranging from 1,000 to 1,600 degrees Celsius, depending on its composition and manufacturing quality. This range allows for versatility in various applications, from metallurgy to ceramics. Industry giants emphasize the importance of rigorous testing and quality assurance measures to ensure that crucibles can withstand extreme conditions without compromising structural integrity or purity. For global buyers looking to source durable silica crucibles, partnering with a trusted supplier that specializes in technical glass products and non-metallic minerals can lead to improved outcomes. By investing in high-quality crucibles, businesses can enhance their operational effectiveness, ultimately leading to more successful outcomes in their respective fields. Commitment to quality and customer service will ensure that every client receives the best solutions tailored to their specific needs.

Effective Ways To Silica Crucible Temperature Range

| Method | Temperature Range (°C) | Typical Applications | Notes |

|---|---|---|---|

| High-Temperature Firing | 1200 - 1600 | Ceramics, Glass | Ideal for vitrified ceramics. |

| Melting Processes | 1600 - 1800 | Metals, Alloys | Compatible with metal casting. |

| Sintering | 800 - 1200 | Powdered Materials | Used in ceramics and composites. |

| Testing Procedures | 500 - 1000 | Material Testing | Testing for thermal stability. |

| Crucible Casting | 900 - 1400 | Metal Alloys | Ensures uniform metal structure. |

The Ultimate Guide to Silica Crucible Temperature Range Pioneers in the Field Where Innovation Meets 2025

O

Oliver Murphy

Top quality materials! The after-sales support is very reliable.

20 May 2025

E

Ella Hughes

The craftsmanship is impressive. Their support staff is fantastic.

12 June 2025

S

Sofia Collins

The products are fantastic, and so is their customer support!

18 June 2025

G

Gavin Perez

The quality is fantastic! The customer service staff is professional and caring.

04 July 2025

A

Aiden King

Fantastic quality products! The after-sales service is very competent.

31 May 2025

C

Charlotte Davis

Exceptional quality! The team is incredibly knowledgeable and attentive.

24 June 2025