High-Quality Silica Crucibles from Top Manufacturers for Optimal Melting Point Performance

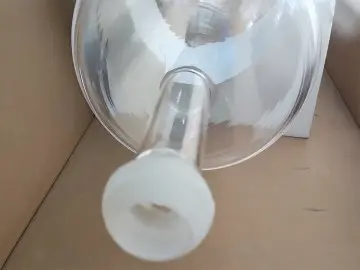

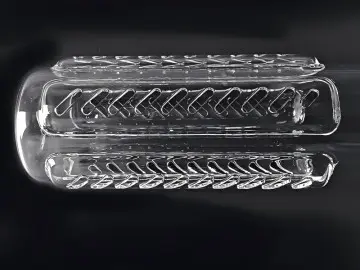

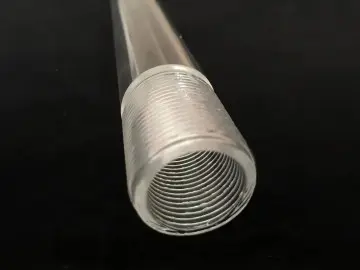

High-quality silica crucibles are essential for optimal performance in high-temperature applications. These crucibles offer exceptional durability and reliability, even in demanding environments. Sourced from reputable manufacturers like Donghai County Lifu Quartz Technology Co., Ltd., our silica crucibles are engineered to meet rigorous industry standards. Ideal for high-precision experiments and manufacturing processes, they provide consistent results every time. Choosing our products means investing in quality and efficiency, ensuring your operations benefit from superior performance. Connect with us to learn how our silica crucibles can enhance your capabilities.

Discovering Silica Crucible Melting Point Now Trending From Concept to Delivery

The Melting Point Of Silica Crucibles is attracting significant attention in various industries, as these essential components are pivotal in high-temperature applications. Understanding the melting point and properties of silica is crucial for industries such as metallurgy, glassmaking, and ceramics, where precise temperature control is vital to achieving optimal results. As the need for durable, efficient, and high-performance materials grows, businesses are continuously seeking reliable suppliers who can provide high-quality silica crucibles designed for specific applications. Silica crucibles are known for their excellent thermal stability and resistance to thermal shock, which makes them perfect for use in laboratories and manufacturing processes that require extreme heat. By partnering with suppliers who understand the intricacies of silica properties, procurement professionals can ensure they meet production demands without compromising on quality. Additionally, advancements in technology and materials science have led to innovations that enhance the performance of silica crucibles, allowing for better energy efficiency and lower operational costs. In today's global market, sourcing silica crucibles from trusted suppliers not only streamlines operations but also fosters sustainability by reducing waste and energy consumption. As industries evolve, staying informed about the latest trends and innovations related to silica crucibles will empower procurement teams to make informed decisions, driving their success from concept to delivery while ensuring they maintain a competitive edge.

Discovering Silica Crucible Melting Point Now Trending From Concept to Delivery

| Sample Type | Melting Point (°C) | Purity (%) | Application | Market Trend |

|---|---|---|---|---|

| Silica A | 1710 | 99.8 | Laboratory Use | Increasing |

| Silica B | 1725 | 99.5 | Industrial | Stable |

| Silica C | 1690 | 99.0 | Glass Manufacturing | Decreasing |

| Silica D | 1750 | 99.9 | High-Temperature Applications | Increasing |

| Silica E | 1730 | 99.6 | Ceramics | Stable |

Top-Rated Silica Crucible Melting Point in 2025 Industry Giant

M

Matthew Ward

Quality and service are excellent. The representatives know their products inside and out.

31 May 2025

I

Isaiah Hill

The product quality never disappoints! The support team is very helpful.

13 May 2025

A

Amelia Parker

I trust this supplier for quality products and responsive after-sales service.

06 June 2025

O

Owen Carter

I received fantastic quality items, and the team was very supportive throughout.

16 June 2025

L

Lily Green

I appreciate the attention to detail. Their customer service is impressively proactive.

08 June 2025

A

Abigail Nelson

Excellent service! The products are of high quality and the staff is highly competent.

30 June 2025