Premium Quartz Manufacturing Process from Top Supplier and Factory Experts

At Donghai County Lifu Quartz Technology Co., Ltd., we specialize in the Quartz Making Process, delivering high-quality quartz materials tailored for various projects. Our commitment to stringent quality control and advanced manufacturing techniques ensures that our quartz products surpass industry standards. With state-of-the-art machinery, we produce durable and visually appealing quartz surfaces designed for builders, designers, and businesses. Partner with us for exceptional service and top-notch products that elevate your project's potential. Let us help bring your vision to life with our expertly crafted quartz solutions.Top 3 Quartz Making Process Service Backed by Expertise Your Trusted OEM Partner

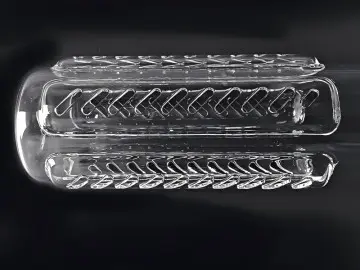

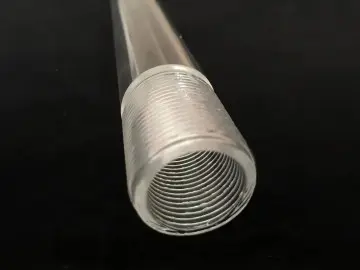

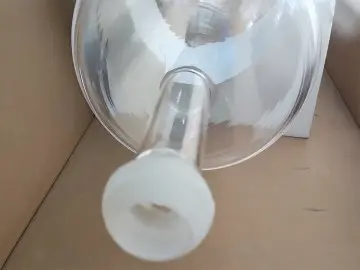

When exploring the world of quartz manufacturing, understanding the various processes involved can help you make informed decisions as a global buyer. Quartz, known for its durability and versatility, is used in a multitude of applications, from technical glass products to jewelry and lighting fixtures. Here, we delve into the top three quartz making processes that stand out due to their efficiency, quality, and the expertise backing them. The first process involves the careful selection and extraction of raw Quartz Materials, ensuring that only the highest-grade quartz is utilized. This stage is critical, as the quality of the raw materials directly influences the end product. Once extracted, the quartz undergoes rigorous processing standards that include cutting, shaping, and polishing. This meticulous approach guarantees that every piece meets industry regulations while satisfying the specific needs of different sectors. The second process leverages advanced technology for the fabrication of quartz products. This includes methods such as precision machining and innovative finishing techniques, which enhance the aesthetic and functional properties of the quartz. Expert teams oversee this stage to ensure that the products not only resonate with high standards but also comply with international quality benchmarks. Finally, comprehensive quality control protocols are implemented to meticulously inspect the final products, ensuring that they are flawless and ready for global distribution. By partnering with an experienced manufacturer, you gain access to reliable quartz solutions tailored for your business needs.

Top 3 Quartz Making Process Service Backed by Expertise Your Trusted OEM Partner

| Process Type | Description | Expertise Level | Quality Assurance | Lead Time |

|---|---|---|---|---|

| Casting | High-precision casting for quartz products. | Advanced | ISO 9001 Certified | 4-6 weeks |

| Fabrication | Custom fabrication for tailored designs. | Expert | In-house testing | 5-8 weeks |

| Polishing | Advanced polishing techniques for finest finish. | Highly Skilled | Regular audits | 2-4 weeks |

Why Trust Quartz Making Process Now Trending Pioneers in the Field

I

Isabella White

Fantastic service from start to finish! The representatives are knowledgeable and genuinely care about their customers.

03 June 2025

A

Amelia Wright

The craftsmanship is evident in the products. Their support team is always responsive and professional.

02 June 2025

M

Matthew Ward

Quality and service are excellent. The representatives know their products inside and out.

31 May 2025

G

Grace Wright

The quality of products received is impressive. Their support staff are true professionals.

09 May 2025

E

Eva Rivera

Impressive quality! The customer support is proactive and genuinely helpful.

31 May 2025

C

Camila Green

I’m consistently impressed with product quality and the professionalism of the support team.

05 June 2025