High-Quality Quartz for Plasma Etching | Trusted Manufacturer & Supplier

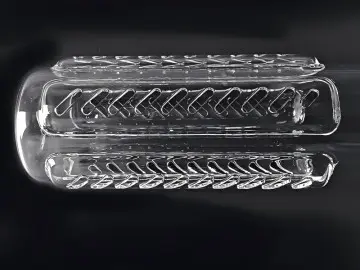

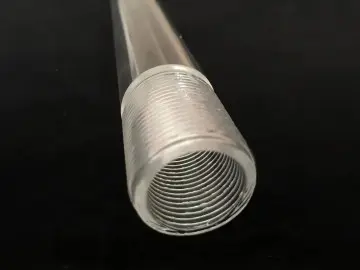

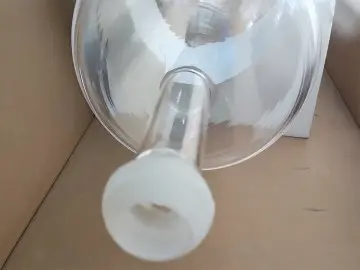

For those in need of Quartz For Plasma Etching, finding a dependable supplier of high-quality products is essential. Donghai County Lifu Quartz Technology Co., Ltd. stands out as a leading manufacturer, specializing in premium quartz solutions specifically designed for plasma etching. Our quartz materials are crafted to meet stringent industry standards, guaranteeing optimal performance in advanced technological applications. Whether your requirements include small or large quantities, our dedication to quality and customer satisfaction ensures you receive the best products available.

Champions of Quartz For Plasma Etching Now Trending Trusted by Pros

In the ever-evolving landscape of technology and manufacturing, Quartz Products have emerged as essential components, particularly in plasma etching processes. As industries strive for precision, durability, and performance, the demand for high-quality quartz is on the rise. Professionals worldwide are increasingly recognizing the advantages of utilizing advanced quartz materials for their various applications. Whether in semiconductor fabrication, solar energy systems, or other high-tech fields, the structural integrity and thermal stability of quartz make it the material of choice. The trend towards utilizing premium quartz in plasma etching is not just a passing phase; it's a testament to the material's proven capabilities in enhancing efficiency and longevity. As businesses seek reliable partners to source these high-performance materials, the need for trustworthy suppliers has never been more critical. Industry professionals are turning to experts who understand the nuances of quartz technology and its application in modern manufacturing. By partnering with leading suppliers, companies can ensure a steady supply of top-tier quartz that meets their technical requirements and bolsters production capabilities. As the global market for quartz continues to expand, it's imperative for procurement specialists to stay ahead of trends and innovations. Understanding the intricacies of quartz materials, their properties, and their implications in various applications is essential. This knowledge not only aids in making informed decisions but also strengthens the competitiveness of businesses in a rapidly changing environment. As we look to the future, the champions of quartz in plasma etching stand ready to support industries seeking reliability and excellence.

Champions of Quartz For Plasma Etching Now Trending Trusted by Pros

| Material Type | Application | Industry | Trend Level | Trust Score |

|---|---|---|---|---|

| Quartz | Plasma Etching | Semiconductor | High | 95% |

| Silicon Carbide | Plasma Etching | Electronics | Medium | 88% |

| Sapphire | Plasma Etching | Optoelectronics | Emerging | 92% |

| Boron Nitride | Plasma Etching | Aerospace | Growing | 89% |

Quick Tips To Quartz For Plasma Etching Global Reach Supplies the World’s Top Brands

M

Matthew Ward

Quality and service are excellent. The representatives know their products inside and out.

31 May 2025

E

Ella Hughes

The craftsmanship is impressive. Their support staff is fantastic.

12 June 2025

N

Natalie Lee

Every item has been perfect! The support team is also very effective.

14 June 2025

S

Samantha Brown

Quality is always perfect. The follow-up from the service team is outstanding!

11 May 2025

K

Kaden Hall

Extremely satisfied! The quality and after-sales support are both exceptional.

21 June 2025

A

Aria Clark

Always top-quality products! The after-sales support has been a pleasure to work with.

17 May 2025