Top Quartz Products for Photolithography: Leading Manufacturers & Recommendations

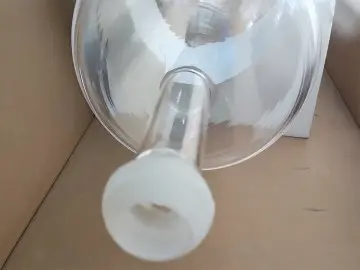

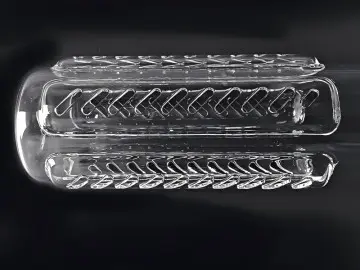

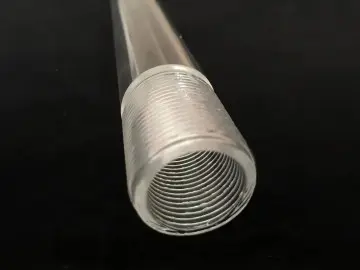

Our premium Quartz for Photolithography is engineered for businesses that prioritize high-quality materials for precision and reliability in their processes. As a trusted supplier, we deliver exceptional products crafted in state-of-the-art facilities. Each quartz piece undergoes rigorous quality checks to ensure you receive the best for your projects. We recognize the significance of consistency and performance in photolithography, and our quartz meets the highest industry standards. By choosing us, you gain more than just quartz; you benefit from a reliable partner in your production journey. Whether in semiconductor manufacturing or optics, our quartz enhances your product's performance and efficiency. The team at Donghai County Lifu Quartz Technology Co., Ltd. is ready to provide tailored solutions that meet your specific needs.Step-by-Step Guide Quartz For Photolithography in 2025 Where Service Meets Innovation

In the rapidly evolving landscape of photolithography, quartz remains a cornerstone material for various applications in semiconductor manufacturing and nano-engineering. As we look towards 2025, it’s vital for global procurement professionals to understand the intricate relationship between service and innovation in sourcing high-quality quartz. The ongoing advancements in technology are reshaping the way quartz is processed, treated, and utilized, offering enhanced performance metrics and reliability in demanding environments. In this step-by-step guide, we will explore the critical aspects that procurement teams should consider when sourcing quartz for photolithography. First, prioritize suppliers that have a robust quality assurance process to ensure that the quartz meets stringent specifications for purity and thermal stability. Moreover, engage with manufacturers who embrace innovation and invest in modern processing techniques, such as precision cutting and advanced surface treatments. These factors not only improve the performance of quartz substrates but also contribute to the overall efficiency of the photolithography process. Furthermore, a strong partnership with suppliers who are committed to timely delivery and consistent support can significantly impact production timelines. As the market continues to demand faster turnaround times without compromising quality, fostering such relationships will be essential. By aligning yourself with suppliers that understand the nuances of photolithography and are dedicated to innovation, you can ensure a seamless supply chain that positions your business for success in the competitive global market.

Step-by-Step Guide Quartz For Photolithography in 2025 Where Service Meets Innovation

| Process Step | Details | Timeframe | Equipment Needed |

|---|---|---|---|

| Substrate Preparation | Cleaning and drying of quartz substrates. | 1-2 hours | Ultrasonic cleaner, dryer |

| Photoresist Application | Coating with a uniform layer of photoresist. | 30 minutes | Spin coater |

| Drying | Soft bake to evaporate solvents. | 15 minutes | Hot plate |

| Exposure | Using lithography equipment to pattern the resist. | 5 minutes | Mask aligner or exposure tool |

| Development | Remove unexposed photoresist. | 10 minutes | Developer solution, rinse station |

| Final Bake | Post-baking to harden features. | 30 minutes | Hot plate |

| Inspection | Quality checks of developed patterns. | 1 hour | Optical microscope, SEM |

How To Evaluate Quartz For Photolithography Service Factory-Direct Excellence

M

Madison Barnes

Great products with an equally great follow-up service!

21 June 2025

D

Daniel Stewart

The quality is impressive. Their customer service is quick and very helpful.

12 May 2025

C

Claire Thompson

I appreciate the professionalism exhibited by the after-sales team. They know their stuff!

16 June 2025

Z

Zoe Gonzalez

The quality was outstanding, and the after-sales service was exceptional.

12 June 2025

S

Samuel Turner

Excellent craftsmanship! The follow-up service was equally commendable.

20 June 2025

M

Max Wilson

Great products and an equally great customer service experience!

10 June 2025