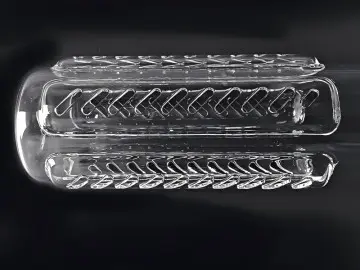

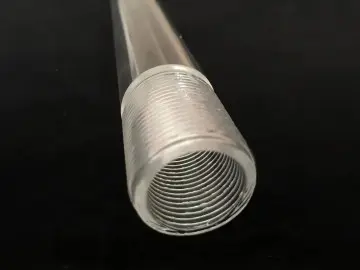

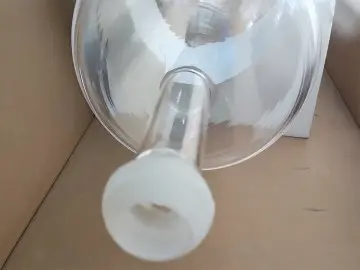

Top Quartz for High-Temperature Processing: Best Factory Products Accepted

For high-temperature processing, our Quartz Products stand out for their exceptional quality. At Donghai County Lifu Quartz Technology Co., Ltd., we provide customized quartz solutions tailored to your unique requirements. Our advanced factory technology guarantees that every product is designed for durability and excellent performance in extreme heat environments. Whether your industry is manufacturing, aerospace, or any other sector that requires dependable materials, our quartz products are built to endure. We prioritize quality and customization, collaborating closely with clients to deliver precisely what you need. Our dedication to excellence is reflected in each item we produce, ensuring the highest standards for your high-temperature applications. Partnering with us means choosing a reliable supplier that understands your needs and delivers superior quartz solutions crafted for demanding conditions. Together, we can achieve remarkable results!

The Secret to Quartz For High Temperature Processing Your Trusted OEM Partner Now Trending

The demand for high-quality quartz for high temperature processing is on the rise, and understanding its properties can set you apart in a competitive marketplace. Quartz is renowned for its ability to withstand extreme temperatures, making it an ideal material for various industrial applications, including semiconductor manufacturing, dental products, and precision instruments. By utilizing advanced technology and expert craftsmanship, manufacturers can produce Quartz Components that meet stringent requirements, ensuring reliability and performance in critical settings. Partnering with a trusted OEM supplier for your quartz needs can streamline your procurement process. An experienced supplier will not only provide a diverse range of quartz products but also offer tailored solutions that enhance efficiency and optimize production. Their expertise in handling non-metallic minerals and technical glass products ensures that you receive top-notch quality that adheres to international standards. Additionally, a commitment to excellence and customer service will ensure that your specific needs are met with precision and care. As the industry continues to evolve, staying abreast of the latest trends and technologies in quartz processing will position you for success. Embracing innovation and choosing the right partner can greatly impact your operational capabilities and overall product quality. Explore the advantages of high-temperature quartz processing and transform your manufacturing processes while boosting your competitive edge.

The Secret to Quartz For High Temperature Processing Your Trusted OEM Partner Now Trending

| Material Type | Max Temperature (°C) | Thermal Conductivity (W/m·K) | Density (g/cm³) | Applications |

|---|---|---|---|---|

| Fused Quartz | 1100 | 1.3 | 2.2 | Semiconductor, Optics |

| Quartz Glass | 1200 | 1.4 | 2.3 | Lighting, High-Power Lasers |

| Synthetic Quartz | 1050 | 1.2 | 2.1 | Telecommunications, Sensors |

| Silica Sleeves | 800 | 0.9 | 1.8 | Heating Elements, Laboratory |

Best Methods To Quartz For High Temperature Processing Factory-Direct Excellence Is The Best

I

Isabella White

Fantastic service from start to finish! The representatives are knowledgeable and genuinely care about their customers.

03 June 2025

O

Oliver Murphy

Top quality materials! The after-sales support is very reliable.

20 May 2025

M

Mia Scott

Superb quality! Their customer service team truly understands the meaning of service.

14 June 2025

C

Charlotte Clark

The quality is consistently high. The staff is very knowledgeable and helpful.

14 May 2025

L

Lily Green

I appreciate the attention to detail. Their customer service is impressively proactive.

08 June 2025

M

Max Wilson

Great products and an equally great customer service experience!

10 June 2025