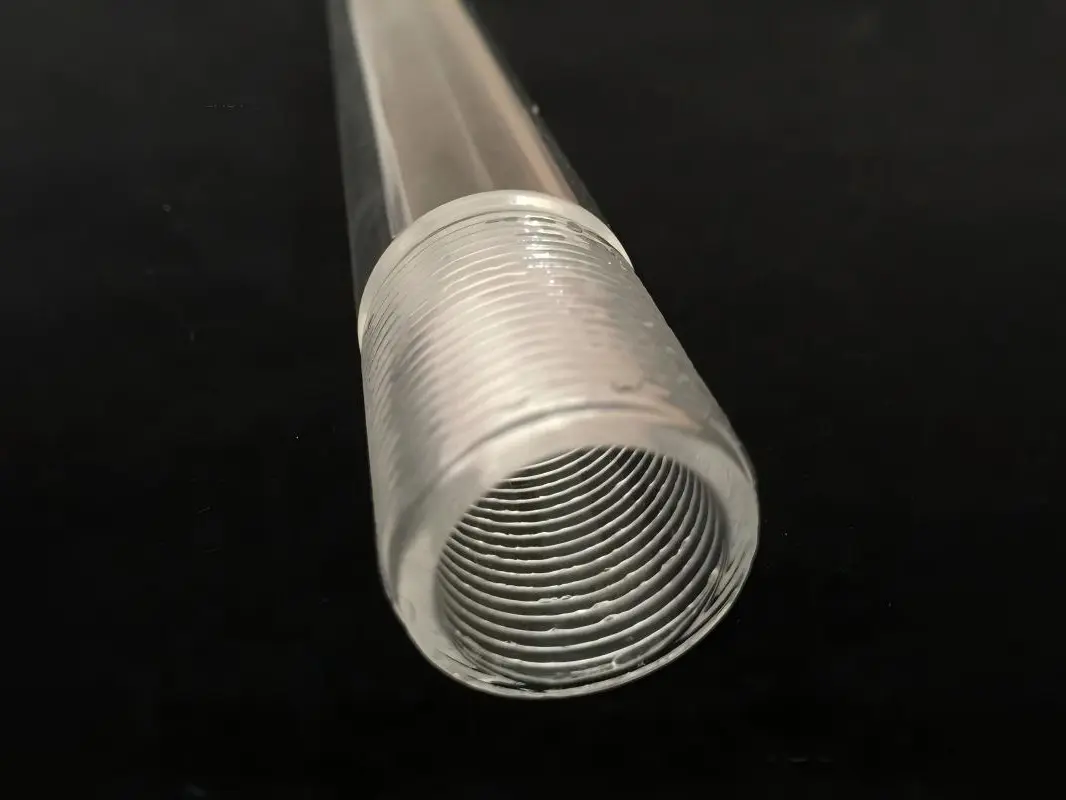

Precision Machined Quartz Tubes – Custom Processing for Industrial Applications

Product Introduction

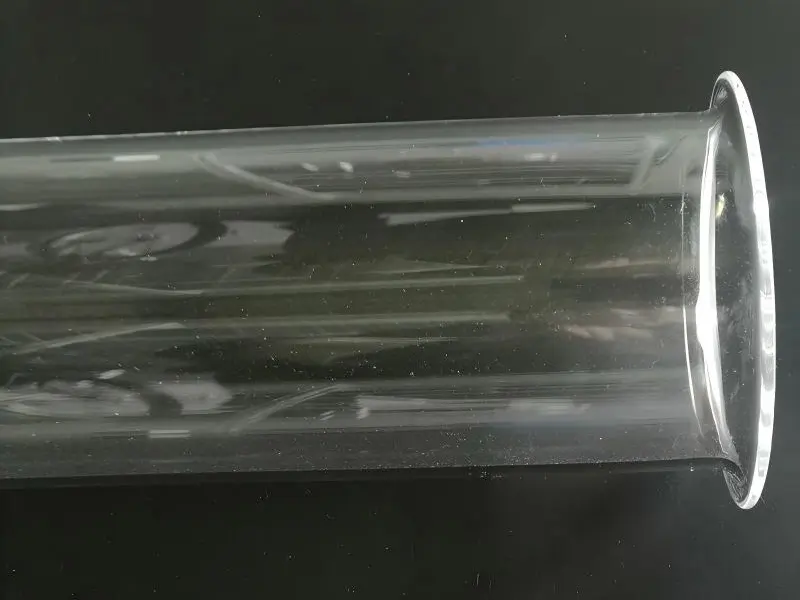

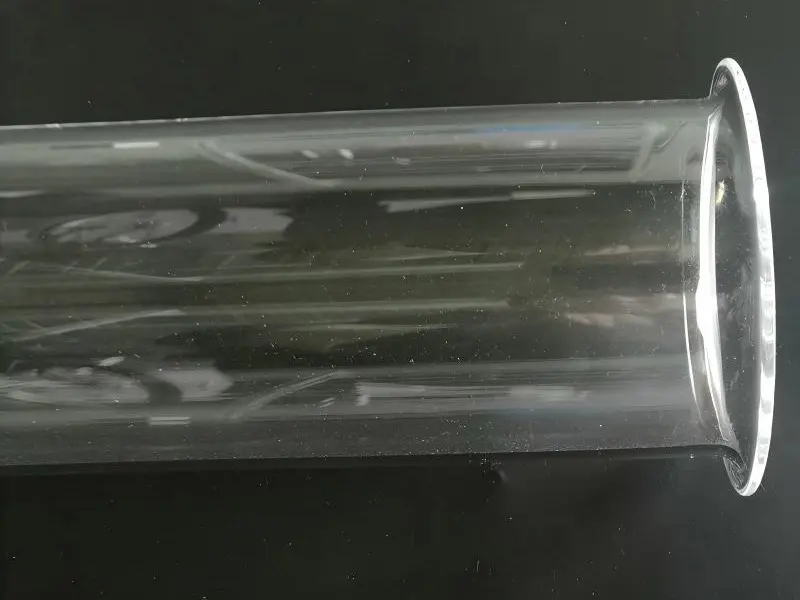

Our Precision Machined Quartz Tubes are manufactured from premium-grade fused silica with a purity exceeding 99.99%, ensuring exceptional optical clarity, high thermal stability, and outstanding chemical resistance. Designed for demanding industrial, laboratory, and commercial applications, these tubes undergo advanced machining processes to meet exact dimensional and performance requirements.

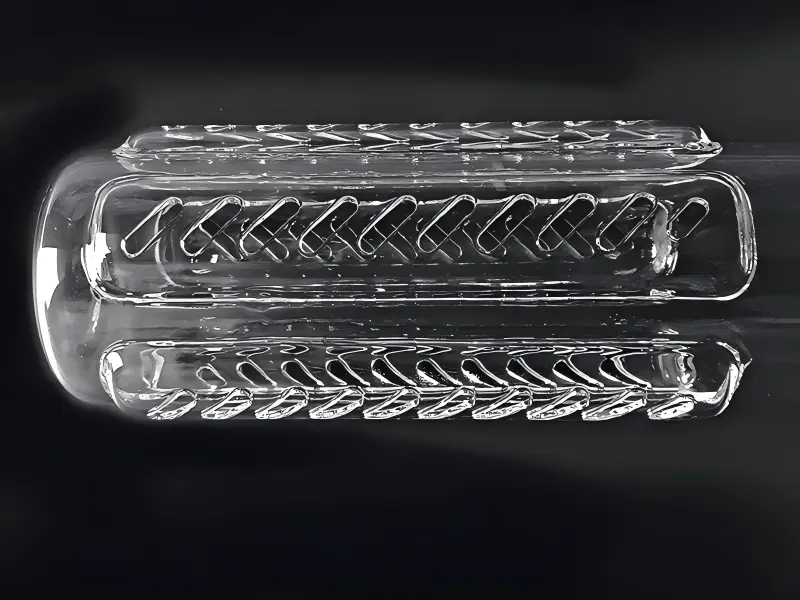

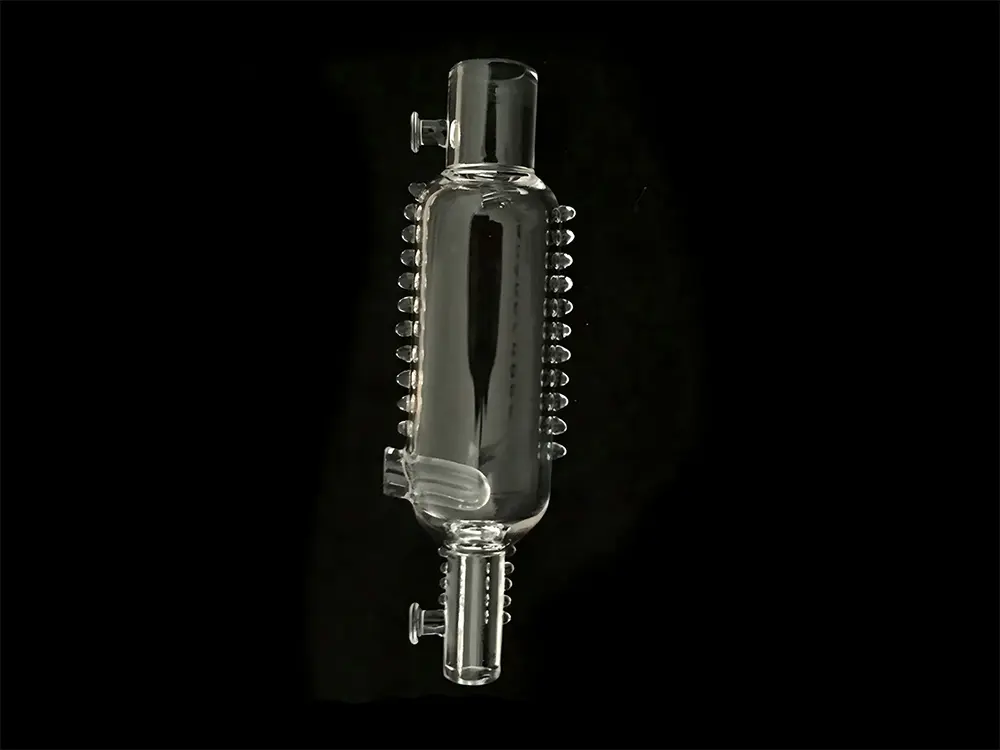

We specialize in custom quartz tube processing, including precision cutting, fire polishing, bending, sealing, and drilling. Whether you require specialized ends such as closed tips, flanges, or tapered sections, or unique dimensions to fit your equipment, our engineering team delivers components with excellent accuracy and consistency.

Key Features

High Purity Material: Over 99.99% SiO₂ content for superior clarity and performance.

Excellent Thermal Resistance: Withstands rapid temperature changes up to 1,100°C without cracking.

Chemical Durability: Resistant to acids, alkalis, and most organic chemicals (except hydrofluoric acid).

Precision Machining: Tight tolerances for diameters, wall thicknesses, and lengths.

Custom Processing: Tailored ends, shapes, and surface finishes to suit specific applications.

Typical Applications

Semiconductor Industry: Wafer processing and diffusion tubes.

UV Sterilization Systems: High light transmission for maximum disinfection efficiency.

Infrared Heating Elements: Stable at high temperatures with excellent heat transfer.

Laboratory Equipment: Chemical analysis and thermal testing devices.

Optical Instruments: UV, visible, and infrared light transmission applications.

Photovoltaic Production: Solar cell manufacturing processes requiring high-purity materials.

Every machined quartz tube is produced under strict quality control to meet international standards. We conduct comprehensive inspections for dimensional accuracy, surface finish, and structural integrity. Our production facilities are equipped with advanced CNC and thermal processing equipment, ensuring stable quality and efficient delivery, even for large-scale orders.

By choosing our Processing Quartz Tube services, you gain access to reliable, high-performance components designed for your exact operational needs. Whether you need a single prototype or mass production, our team offers technical expertise, competitive pricing, and responsive support to ensure your projects succeed.

Contact us today to discuss your custom quartz tube requirements and discover how our precision machining capabilities can enhance your industrial applications.

description2