Breakthrough in High-Purity Quartz Tube Production Enhances Industrial Applications

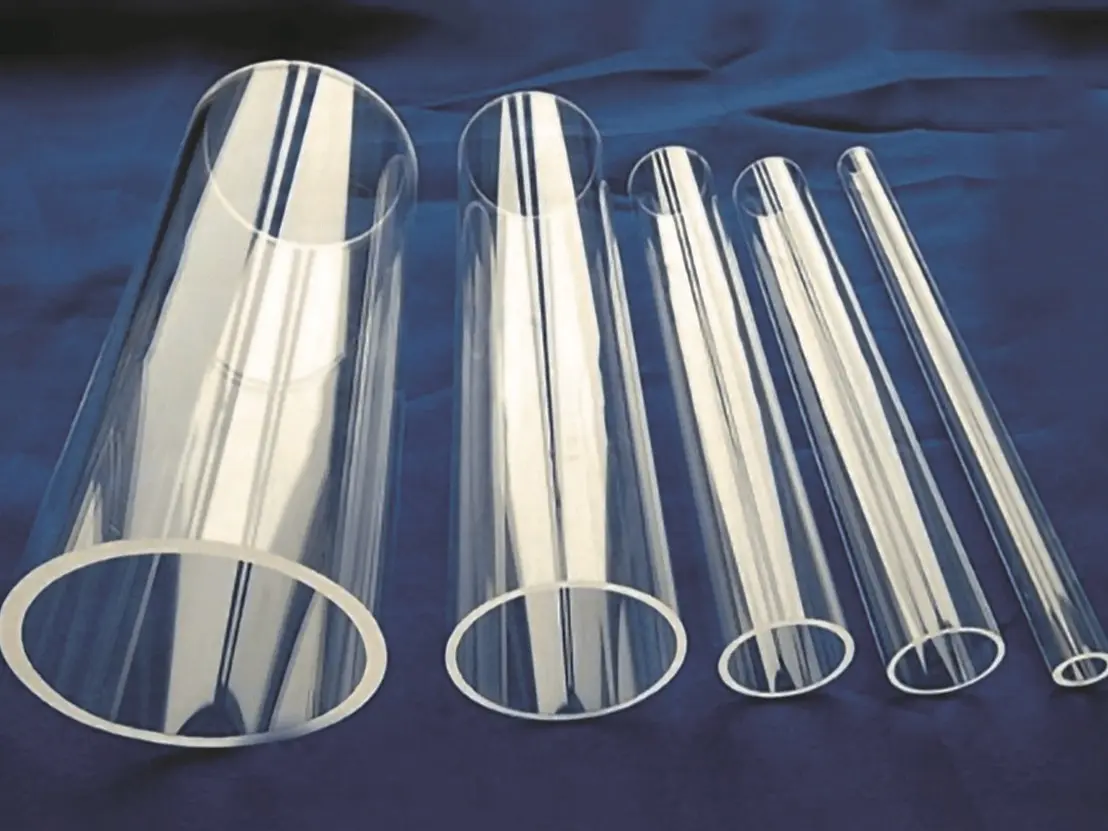

In a significant advancement for materials science, the production of high-purity Quartz Tubes has reached new technical milestones, delivering unmatched performance for industrial and scientific sectors. Utilizing advanced refining and manufacturing techniques, leading producers have achieved silica purity levels exceeding 99.99%, ensuring superior optical clarity, exceptional thermal stability, and outstanding resistance to chemical corrosion.

Quartz tubes have long been valued for their transparency across ultraviolet, visible, and infrared wavelengths, making them indispensable in high-precision optical instruments, semiconductor manufacturing, and UV sterilization systems. The latest production improvements now offer enhanced light transmittance, enabling greater efficiency in UV curing, photolithography, and other light-dependent processes.

One of the most notable upgrades is the ability of these quartz tubes to withstand rapid thermal fluctuations of up to 1,100°C without cracking or deforming. This high thermal shock resistance is crucial for industries operating in extreme temperature environments, such as high-temperature furnaces, laboratory heating systems, and aerospace material testing. The smooth, fire-polished surfaces minimize contamination, while the non-porous structure resists acids, alkalis, and most organic chemicals, ensuring a longer operational lifespan.

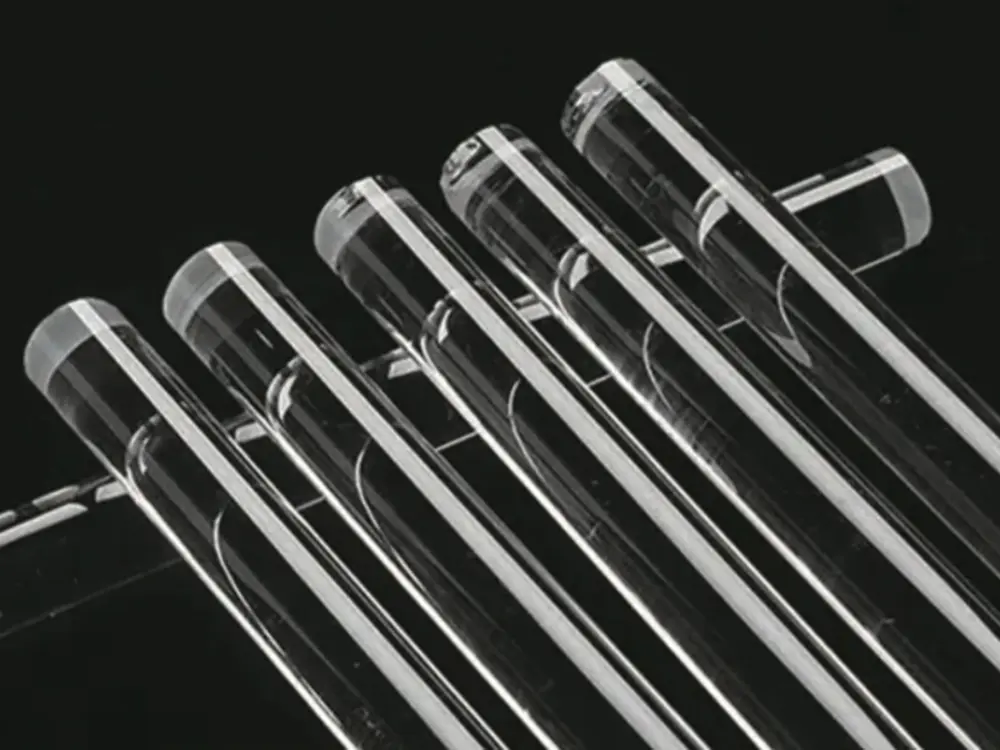

Manufacturers are also expanding customization capabilities. Clients can now order quartz tubes with tailored diameters, wall thicknesses, and lengths to meet exact application needs. Specialized ends—such as closed tips, flanges, and tapered shapes—are increasingly available, along with advanced processing like bending, sealing, and engraving. This flexibility supports diverse applications from fiber optic cable protection to precision optical assemblies.

Industry experts note that this technological leap is already influencing multiple sectors. Electronics manufacturers are using these tubes to enhance semiconductor wafer production, water treatment companies are incorporating them into high-efficiency UV disinfection systems, and solar panel producers rely on them for critical process stability.

Market forecasts suggest that global demand for high-purity quartz tubes will continue to grow steadily, driven by the expansion of renewable energy infrastructure, advancements in medical sterilization technology, and the increasing need for precision manufacturing in electronics and photonics. With competitive pricing, stable supply chains, and enhanced quality control, modern quartz tubes are positioned to become an even more vital component in high-tech industries worldwide.