Large Process Quartz Tubes – High-Purity Industrial Quartz Glass Solutions

Product Introduction

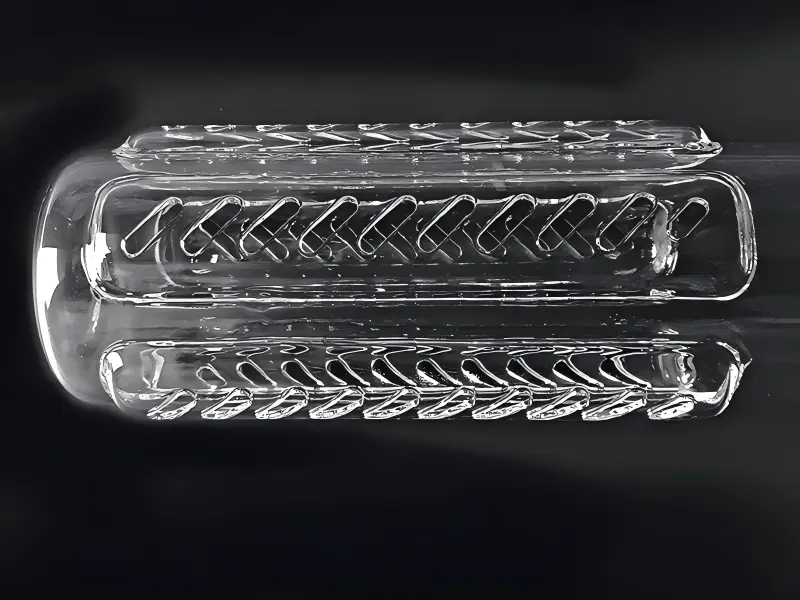

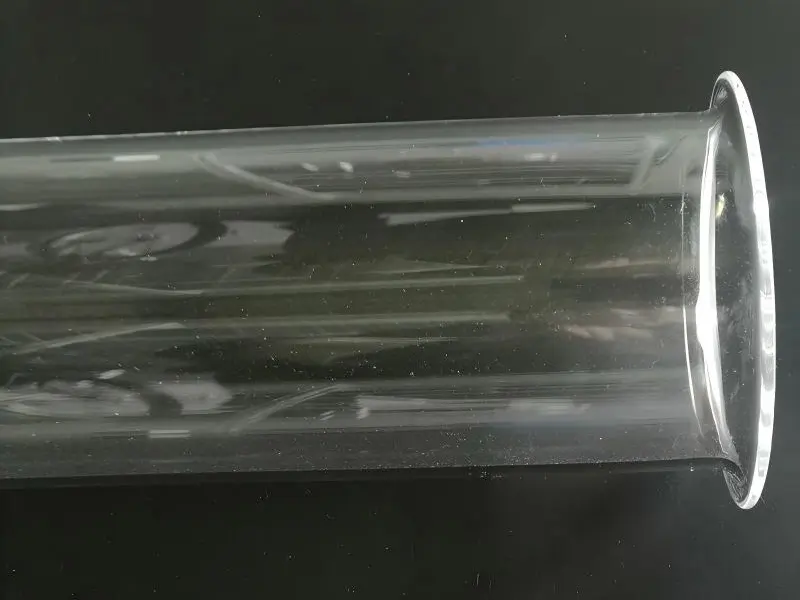

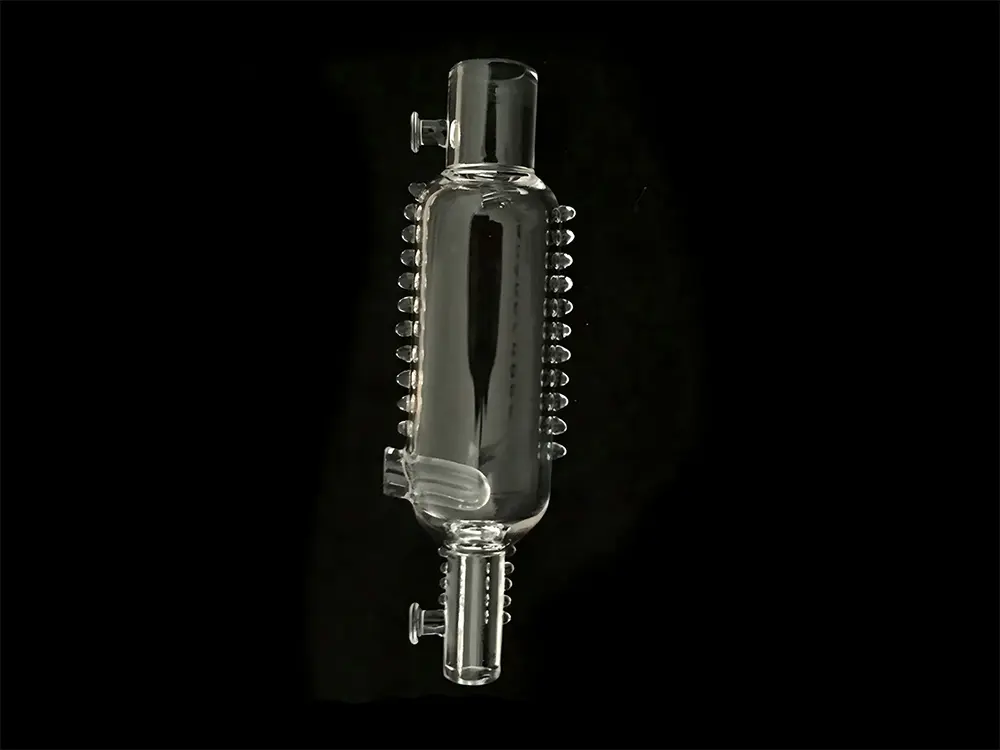

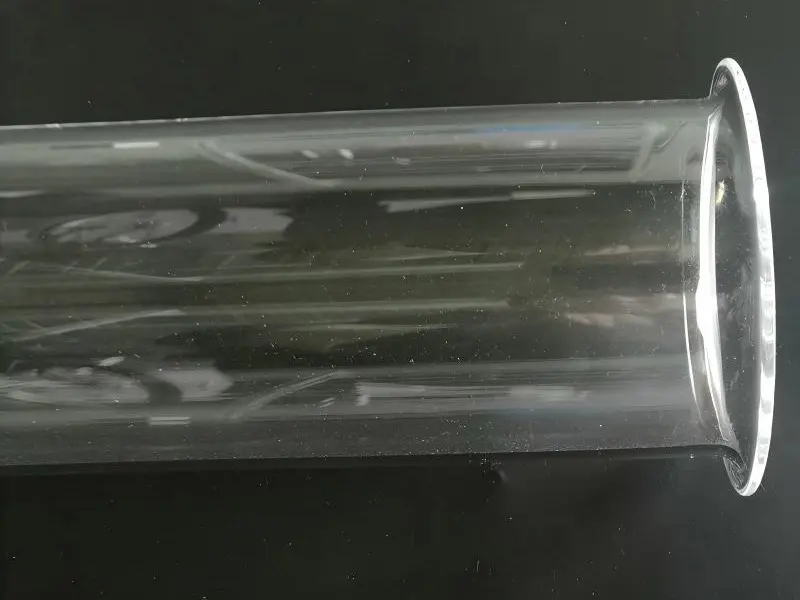

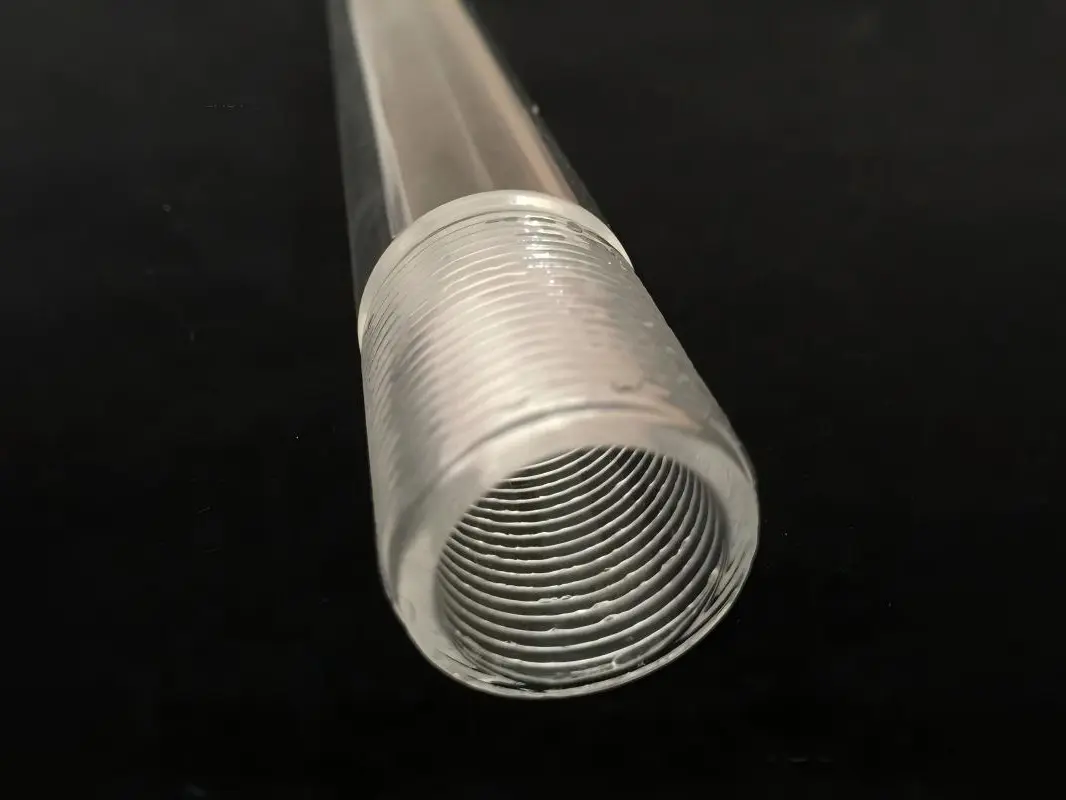

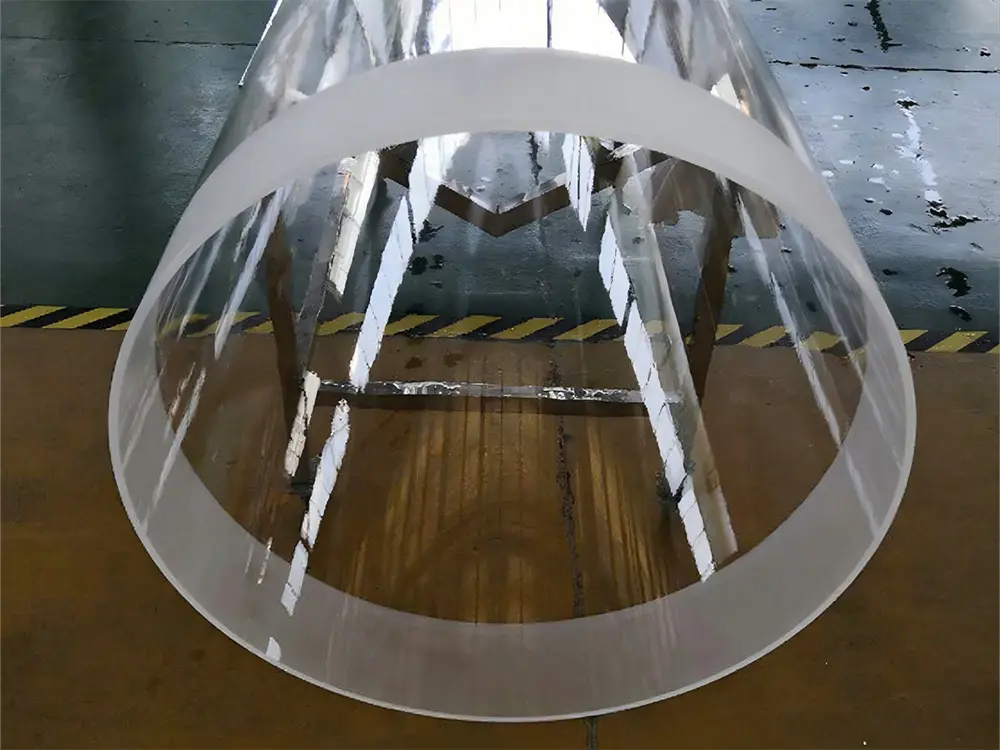

Our Large Process Quartz Tubes are manufactured from premium-grade fused silica with a purity exceeding 99.99%, delivering superior optical clarity, high thermal stability, and excellent chemical resistance. Engineered for heavy-duty industrial and scientific applications, these tubes are ideal for processes requiring large dimensions, high temperature endurance, and long service life.

Designed to perform in extreme environments, our large quartz tubes can withstand rapid temperature changes up to 1,100°C without cracking or deformation. Their non-porous surface prevents contamination and resists acids, alkalis, and most organic chemicals (except hydrofluoric acid), ensuring long-term durability even under continuous use.

We offer custom fabrication options to meet your exact processing needs. This includes precision cutting to specific lengths, fire polishing for smooth edges, bending for specialized designs, and sealing or shaping for unique equipment requirements. Large process quartz tubes are available in a wide range of outer diameters and wall thicknesses, allowing for seamless integration into high-capacity systems.

Key Features

High Purity Material – Over 99.99% SiO₂ content for superior performance.

Large-Scale Processing Capability – Suitable for oversized industrial applications.

Outstanding Thermal Resistance – Stable under extreme heat and rapid temperature changes.

Excellent Optical Properties – High transmittance for UV, visible, and IR applications.

Chemical Durability – Resists most acids, alkalis, and industrial chemicals.

Typical Applications

Semiconductor manufacturing and wafer processing

High-capacity UV sterilization systems

Large-scale infrared heating elements

Industrial high-temperature furnace tubes

Photovoltaic panel production lines

Scientific research and optical equipment manufacturing

Every large process quartz tube is produced under strict quality control procedures, including dimensional accuracy checks, surface finish inspections, and structural integrity testing. Our advanced manufacturing facilities are equipped to handle both small-batch custom orders and large-volume production with consistent quality and timely delivery.

By choosing our Large Process Quartz Tubes, you gain access to precision-engineered, high-performance components that enhance efficiency and reliability in demanding industrial processes. Contact our team today to discuss your specifications and discover how our large quartz solutions can meet your operational needs.

description2