Large Process Quartz Tubes – High-Purity Industrial Quartz Glass Solutions

Product Introduction

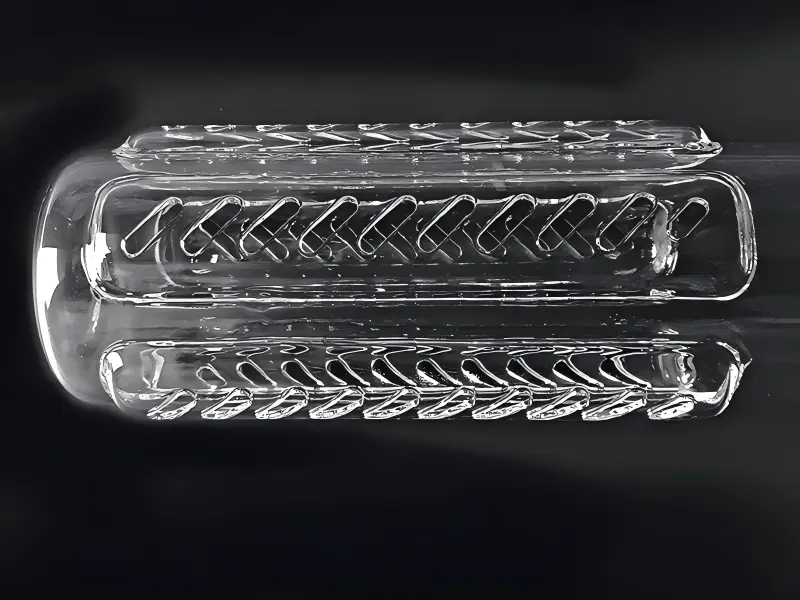

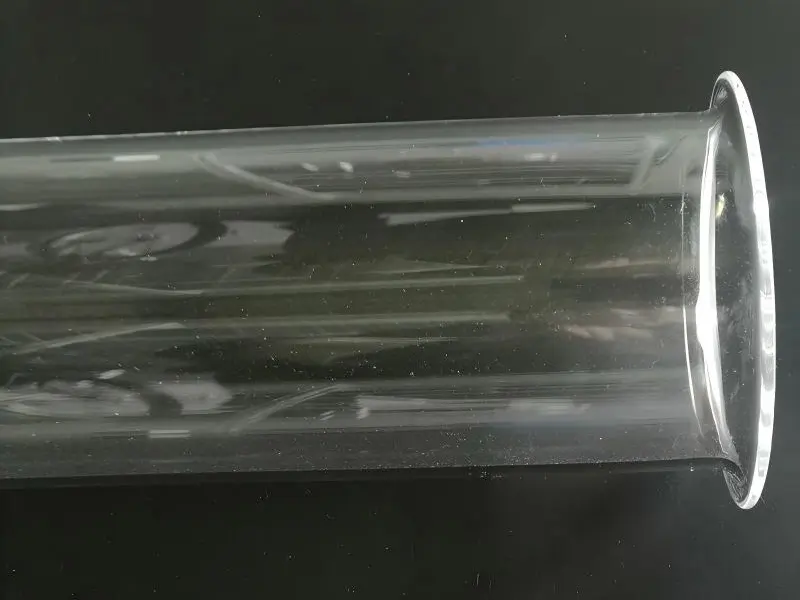

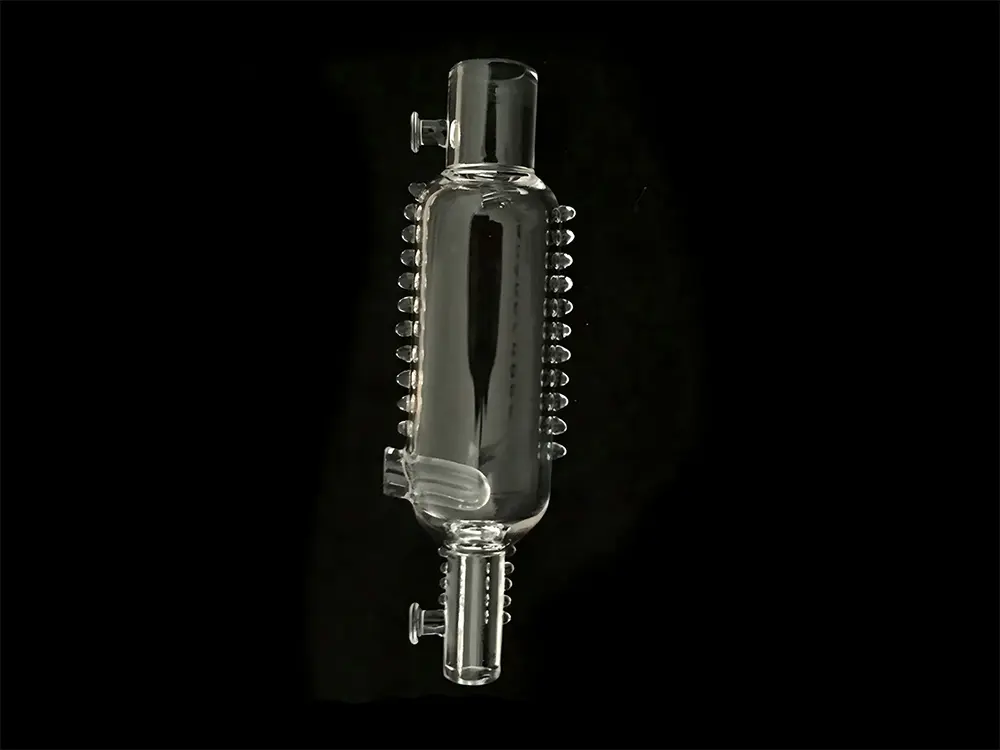

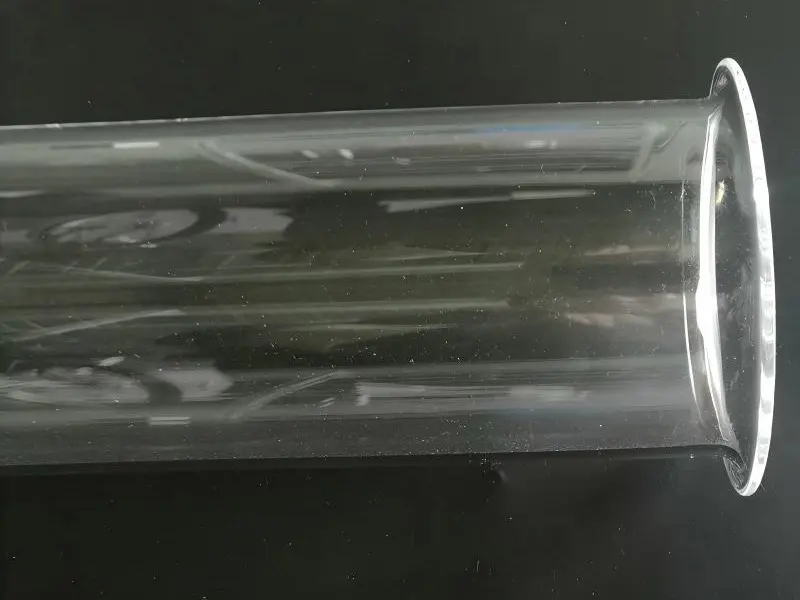

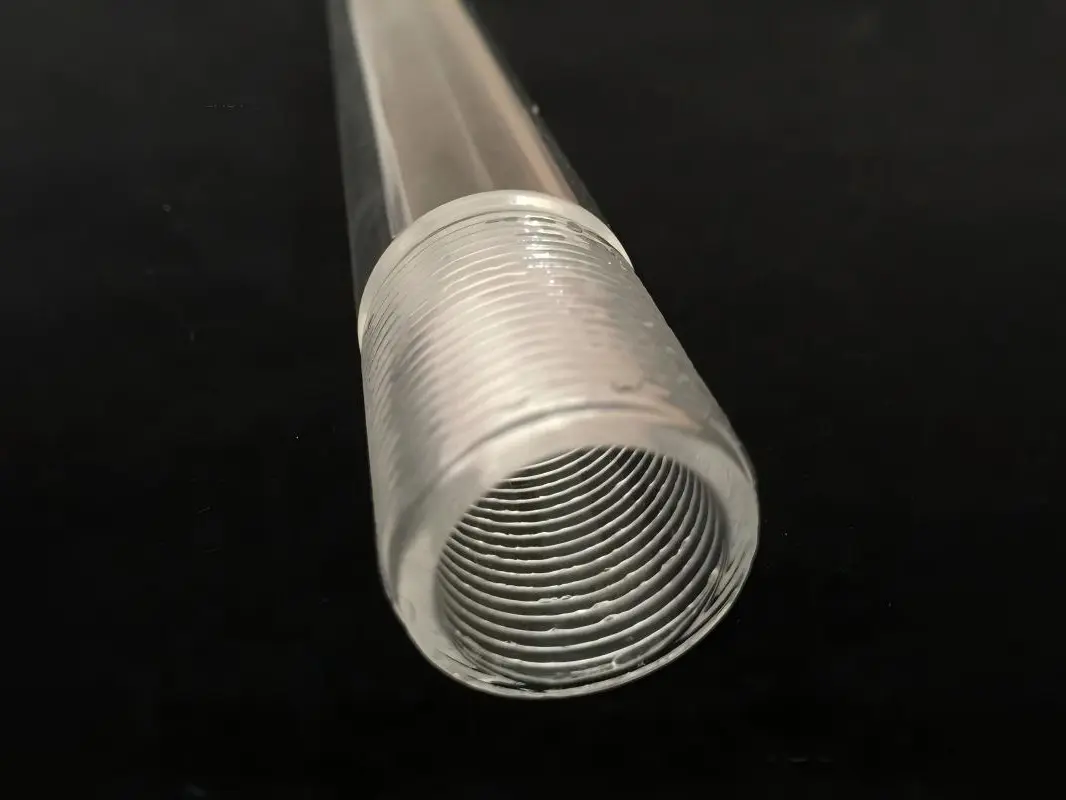

Our Large Process Quartz Tubes are manufactured from premium-grade fused silica with a purity exceeding 99.99%, delivering superior optical clarity, high thermal stability, and excellent chemical resistance. Engineered for heavy-duty industrial and scientific applications, these tubes are ideal for processes requiring large dimensions, high temperature endurance, and long service life.

Designed to perform in extreme environments, our large quartz tubes can withstand rapid temperature changes up to 1,100°C without cracking or deformation. Their non-porous surface prevents contamination and resists acids, alkalis, and most organic chemicals (except hydrofluoric acid), ensuring long-term durability even under continuous use.

We offer custom fabrication options to meet your exact processing needs. This includes precision cutting to specific lengths, fire polishing for smooth edges, bending for specialized designs, and sealing or shaping for unique equipment requirements. Large process quartz tubes are available in a wide range of outer diameters and wall thicknesses, allowing for seamless integration into high-capacity systems.

Key Features

High Purity Material – Over 99.99% SiO₂ content for superior performance.

Large-Scale Processing Capability – Suitable for oversized industrial applications.

Outstanding Thermal Resistance – Stable under extreme heat and rapid temperature changes.

Excellent Optical Properties – High transmittance for UV, visible, and IR applications.

Chemical Durability – Resists most acids, alkalis, and industrial chemicals.

Typical Applications

Semiconductor manufacturing and wafer processing

High-capacity UV sterilization systems

Large-scale infrared heating elements

Industrial high-temperature furnace tubes

Photovoltaic panel production lines

Scientific research and optical equipment manufacturing

Every large process quartz tube is produced under strict quality control procedures, including dimensional accuracy checks, surface finish inspections, and structural integrity testing. Our advanced manufacturing facilities are equipped to handle both small-batch custom orders and large-volume production with consistent quality and timely delivery.

By choosing our Large Process Quartz Tubes, you gain access to precision-engineered, high-performance components that enhance efficiency and reliability in demanding industrial processes. Contact our team today to discuss your specifications and discover how our large quartz solutions can meet your operational needs.

About Us

Donghai County Lifu Quartz Technology Co., Ltd.. is located in the beautiful Seaside city Lianyungang, Jiangsu, China. We are specialized in the research, manufacture and sales of quartz products. With advanced equipment, strong technical capabilities, perfect inspection methods and strict quality assurance system, we mainly manufacture and export quartz products, like quartz plate, quartz tube, quartz crucible, transparent quartz glass tube, oxidized quartz glass tube, quartz glass diffusion tube, grinding mouth quartz glass tube, quartz glass slide, quartz boat, quartz ware, quartz mound, quartz rod, light stick, light building material, medical device, scientific instruments, etc. Our products are sold to more than twenty provinces within China. Meanwhile, they are exported to lots of other countries and regions, like South Korea, Southeast Asia, Europe, America, etc. and are very popular among our clients, Southeast Quartz has been honored as Jiangsu High Technology Enterprise and has passed ISO9001:2000 Quality Management System Certification. We always remind ourselves that “Client is the Center, Quality is the key”. We will do our 100% efforts to make our clients satisfied!

Technical Glass Products The company's leading products include quartz furnace tubes, secondary molding straight-through tubes, negative pressure furnace tubes, quartz cups, quartz brackets, quartz source bottles, waste liquid bottles, quartz furnace doors, and secondary charging quartz equipment, which have been widely used in light sources, photovoltaics, optical fibers, optics and semiconductor fields.

description2