High-Purity Quartz Glass Low Pressure Diffusion Furnace Tubes – Southeast Quartz China Manufacturer

Product Introduction

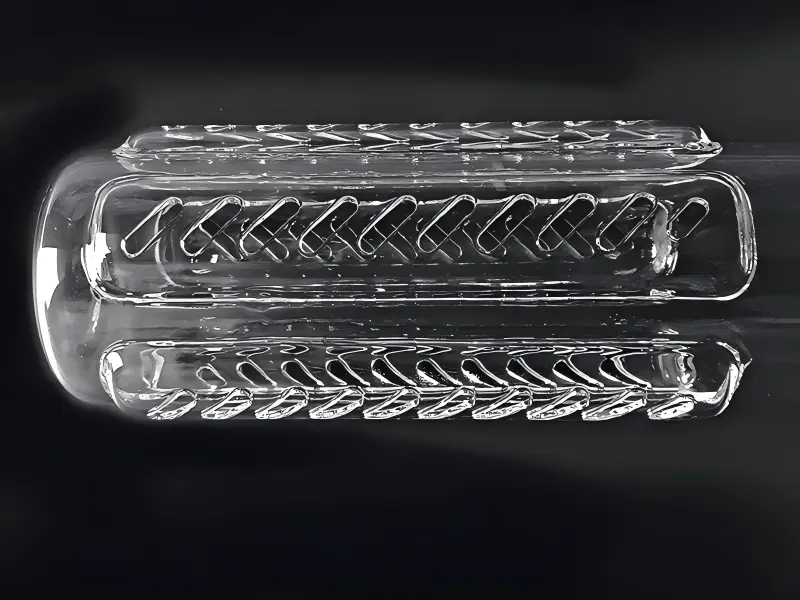

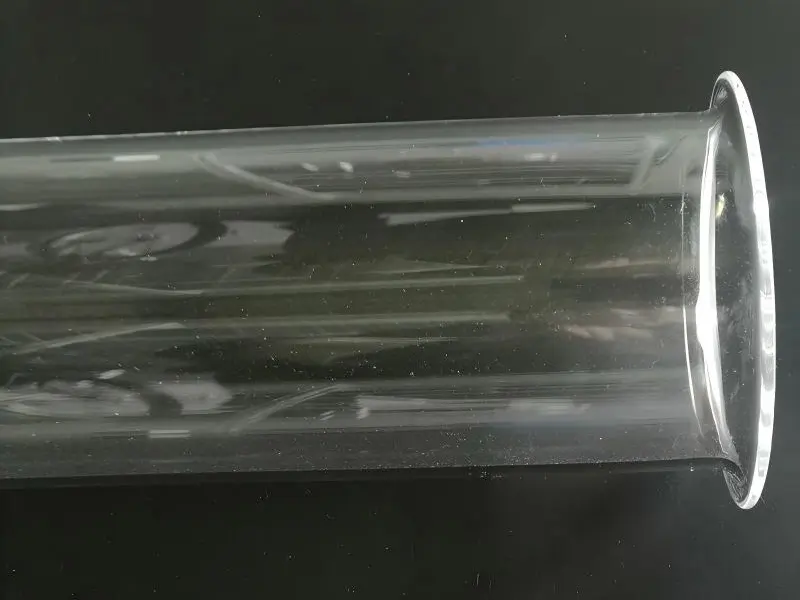

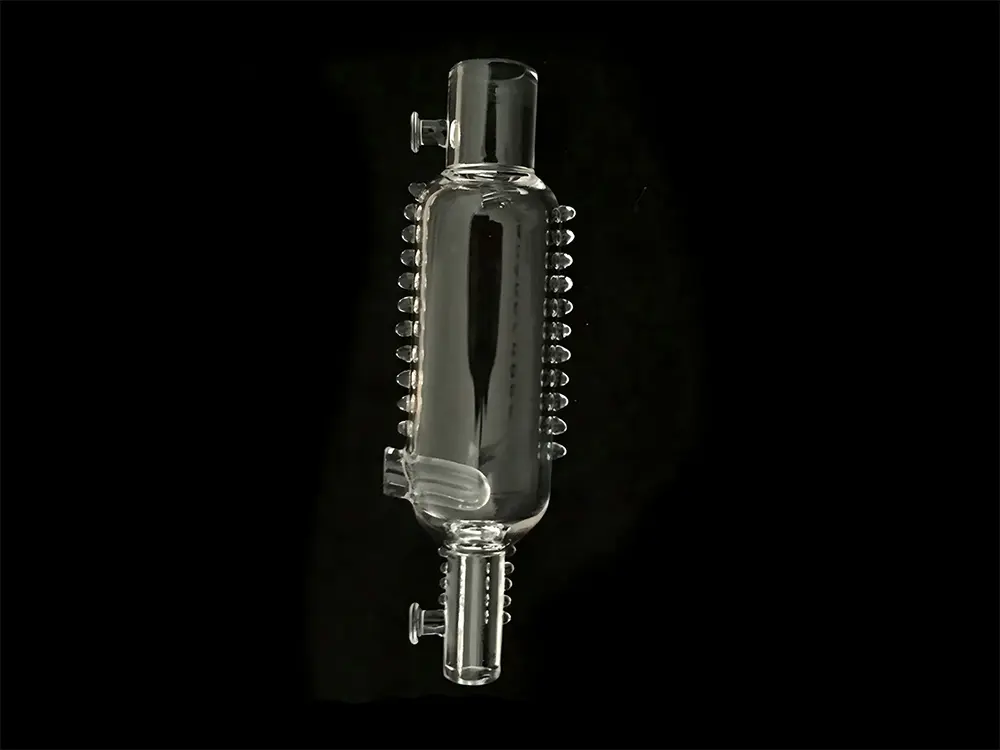

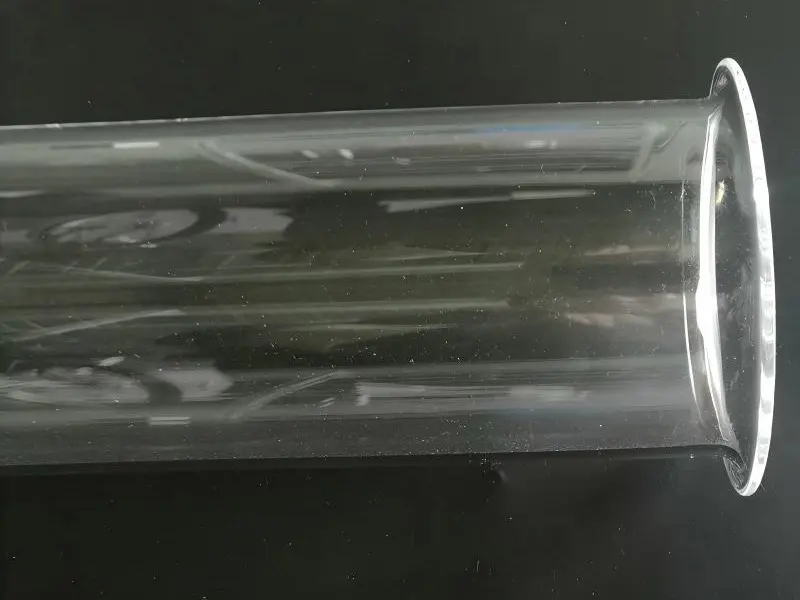

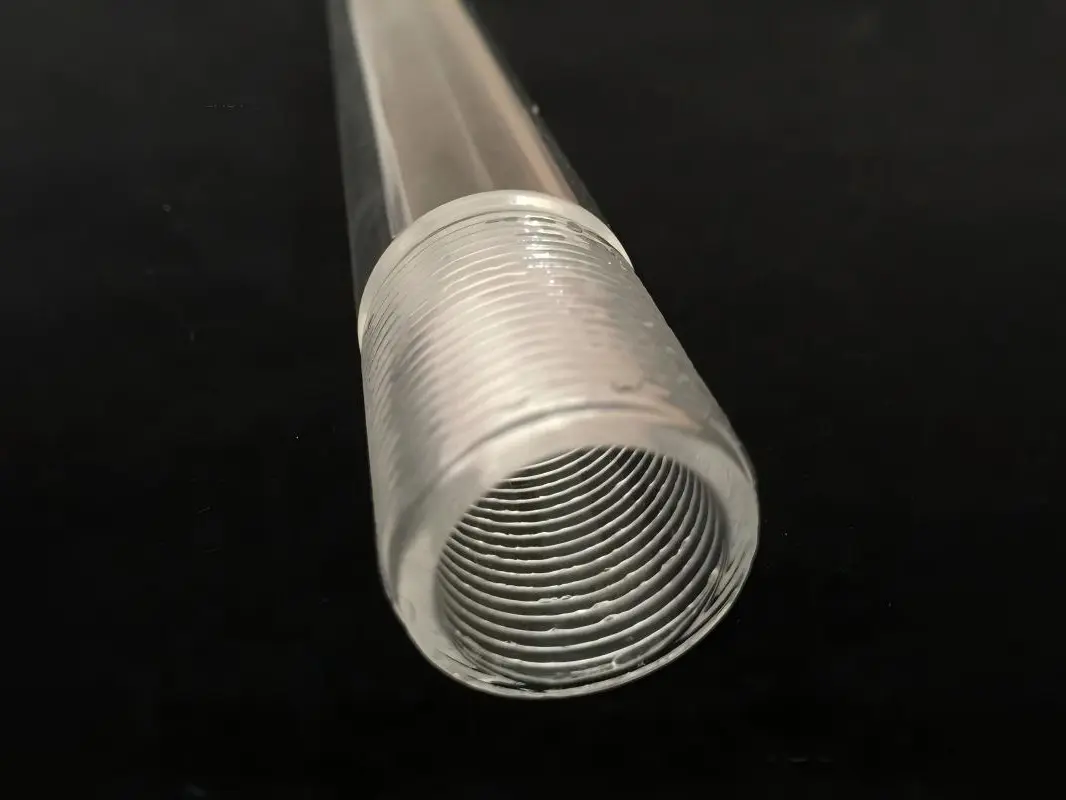

Our Quartz Glass Low Pressure Diffusion Furnace Tubes are crafted from ultra-high purity fused silica, with a SiO₂ content exceeding 99.99%, ensuring superior optical clarity, excellent mechanical strength, and outstanding thermal stability. Manufactured by Southeast Quartz China, these tubes are specifically engineered for low pressure diffusion processes used in semiconductor fabrication, photovoltaic production, and advanced laboratory applications.

With their smooth, polished inner surface, our furnace tubes minimize particle contamination, allowing precise control of thermal and chemical environments during diffusion, oxidation, or annealing processes. They exhibit exceptional transmittance in ultraviolet, visible, and infrared light ranges, making them suitable for both high-temperature heating and optical-based monitoring systems.

Key Features

Ultra-High Purity Quartz Glass – Over 99.99% SiO₂ for stable performance in cleanroom environments.

Excellent Thermal Resistance – Can withstand continuous use at temperatures up to 1,050°C and rapid thermal cycling.

Low Pressure Design – Optimized for controlled atmospheric processing in semiconductor and photovoltaic manufacturing.

Chemical Resistance – Non-porous and resistant to most acids, alkalis, and organic solvents (excluding HF).

Precision Manufacturing – Accurate dimensions, uniform wall thickness, and smooth finish for stable sealing and installation.

Typical Applications

Semiconductor wafer diffusion and oxidation

Solar cell production lines

LPCVD (Low Pressure Chemical Vapor Deposition) processes

High-purity gas heating and transfer

Advanced materials research and laboratory furnace systems

We offer a wide range of sizes, including variations in outer diameter, wall thickness, and length, to suit different furnace models and process requirements. Our customization services cover end configurations (open, closed, flanged), fire polishing, and special surface treatments to meet strict operational specifications.

Every quartz glass furnace tube undergoes stringent quality inspection for structural integrity, dimensional accuracy, and surface cleanliness before shipment. With our advanced production capabilities, we ensure a consistent supply of high-quality furnace tubes, meeting international semiconductor industry standards.

Choosing Southeast Quartz China means partnering with a trusted manufacturer committed to delivering durable, high-performance quartz solutions for critical applications. Contact us to discuss your specifications and request a tailored quotation today.

description2