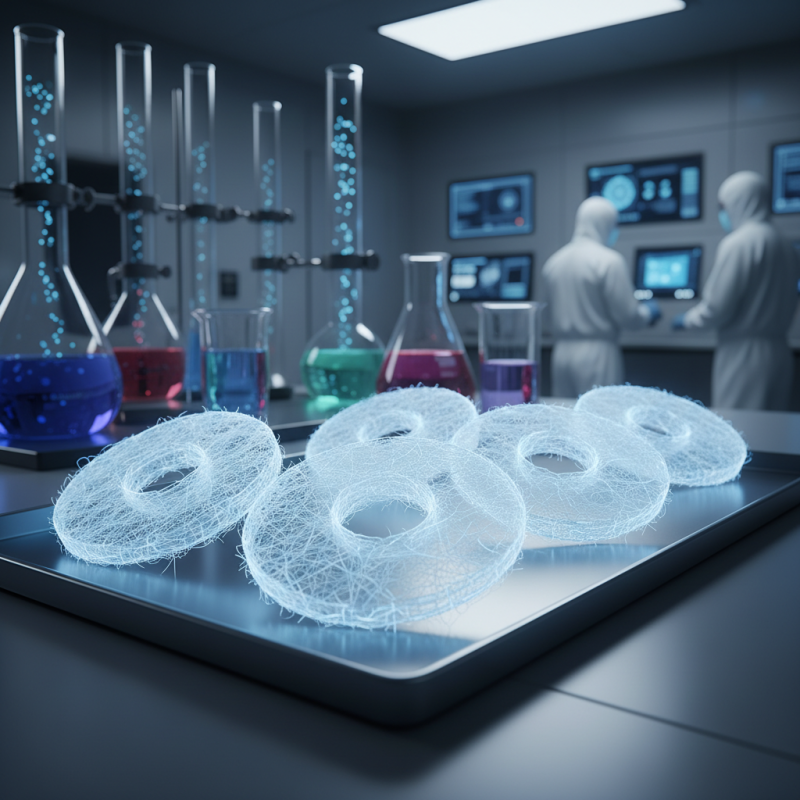

The demand for enhanced filtration efficiency has led to a significant rise in the use of Quartz Microfiber Filters across various industries. According to a recent industry report by Filtration Today, the market for these filters is projected to grow by 15% annually through 2026. This growth is driven by the need for superior particle capture, especially in areas such as cleanroom environments and chemical processing.

Dr. Emily Chen, a leading expert in filtration technologies, emphasizes their importance: “Quartz Microfiber Filters outperform traditional options by providing exceptional filtration rates.” Such performance is critical in minimizing contamination risks, thus ensuring product quality and safety. However, as the demand increases, many manufacturers face challenges in maintaining consistent quality and performance across different batches.

Incorporating state-of-the-art materials is essential but may lead to unforeseen issues. Some filters may not perform as expected under varying conditions. This uncertainty calls for a closer examination of current production methods. Companies must reflect on how to adapt their processes to meet the rising standards of filtration efficiency. The journey toward optimized Quartz Microfiber Filters continues, with room for improvement and innovation.

The rise of quartz microfiber filters is reshaping filtration technology. These filters are crafted from extremely fine fibers, allowing them to trap particles of varying sizes. This innovation enhances efficiency, especially in air and liquid purification. They are designed to provide superior performance compared to traditional filters.

Quartz microfiber filters excel in applications requiring high filtration efficiency. They can capture allergens and pollutants effectively. However, while they perform well, issues still arise during maintenance. Regular cleaning is essential, but some users overlook this step. This negligence can lead to reduced effectiveness over time.

Many industries are adopting these filters, yet understanding their limitations is crucial. They aren't a one-size-fits-all solution. Their effectiveness can vary based on the environment and specific contaminants. Users must assess their individual needs and workflows. The balance between performance and maintenance should inspire reflection on user practices.

The demand for advanced filtration systems is rising. Quartz microfiber filters are leading in this trend. These filters enhance efficiency significantly. Recent industry reports state that these filters can reduce particle contamination by over 95%. This efficiency is crucial in various applications, especially in healthcare and industrial sectors.

Modern quartz microfiber filters boast key features that optimize performance. They have high dirt-holding capacity. This allows for longer service life and reduces the frequency of changes. Many filters use fine fibers that trap smaller particles effectively. Research highlights that filters with a fiber diameter of less than 1 micron can achieve superior efficiency. Despite these advantages, users must be cautious. Improper use can lead to decreased performance over time.

Regular maintenance is essential. A well-maintained quartz microfiber filter can outperform others. However, not everyone follows the recommended protocols. This negligence can erode the advantages these filters provide. Ensuring proper installation and routine checks is vital to maximize efficiency. Data shows that poorly maintained filters can reduce effectiveness by as much as 30%. Thus, understanding both the strengths and limitations of quartz microfiber filters is important for users in all sectors.

When it comes to advanced filtration, quartz microfiber filters stand out for their efficiency. According to a recent industry report, these filters can achieve up to 99.9% particle retention. This level of retention significantly reduces airborne contaminants. Their structure allows for deep penetration of particles, enhancing overall air quality.

The comparative analysis of available filters indicates variations in performance. Some filters demonstrate higher airflow resistance, limiting efficiency. A report from the Filtration Society highlights that filters with a lower basis weight might not capture fine particles effectively. Moreover, material durability plays a critical role. Many filters degrade over time, which can compromise filtration rates.

Testing shows that while some filters excel in specific environments, others may underperform. It is crucial to evaluate conditions such as humidity and temperature. Filters designed for dry environments may fail in humid areas. This mismatch can lead to wasted resources and suboptimal air quality. Understanding these nuances allows for better choices in filter selection.

Quartz microfiber filters are increasingly popular in diverse industries due to their exceptional filtration properties. In the healthcare sector, these filters help remove harmful pathogens and particulate matter from air and liquids. A study reveals that using quartz microfiber filters can capture up to 99% of airborne particles. This capability is crucial in hospitals, where maintaining clean environments is necessary to prevent infections.

In the automotive industry, quartz microfiber filters play a significant role in improving air quality inside vehicles. They are effective in filtering out fine dust and allergens. Reports indicate that these filters can enhance the efficiency of HVAC systems by up to 30%. However, some manufacturers face challenges in ensuring consistent filter performance. This inconsistency may lead to a need for frequent maintenance, increasing operational costs.

Furthermore, in manufacturing processes, quartz microfiber filters are essential for controlling emissions. They filter toxins released during production. Unfortunately, not all industries adopt these filters consistently. Some sectors still rely on outdated filtration systems, which may compromise safety standards. As industries evolve, the demand for high-quality filtration solutions continues to rise, highlighting the need for better awareness of the benefits of quartz microfiber filters.

This chart illustrates the filtration efficiency percentages of quartz microfiber filters across various industries, highlighting their importance in enhancing filtration processes.

The filtration industry is witnessing significant advancements in quartz microfiber technology. Reports indicate that the use of quartz microfibers can enhance filtration efficiency by up to 98%. This improvement is primarily due to their fine fiber structure, which captures smaller particles and pollutants effectively. The ongoing research highlights that these filters can outperform traditional materials, making them a popular choice in various sectors, including air and liquid filtration.

Innovation does not come without challenges. While quartz microfibers show promise, the production process needs optimization. Current manufacturing methods can be costly and energy-intensive. There’s a need for sustainable practices that minimize waste and lower production costs. Many companies are exploring eco-friendly alternatives, yet the shift is slow.

Moreover, user feedback suggests that while performance is crucial, maintenance remains a concern. As filtration efficiency rises, users must adapt to these new systems, which may require different care and replacement schedules. Striking a balance between efficiency and practicality is essential for the future of quartz microfiber filters. Continuous innovation will play a key role in addressing these issues as the market evolves.