The Quartz Glass Crucible is an essential tool in various scientific and industrial applications. Its unique properties make it ideal for high-temperature experiments. According to a recent market report, the global demand for quartz glass crucibles is projected to grow significantly in the coming years. This growth reflects the increasing use of quartz glass in sectors such as semiconductor manufacturing and material science.

Researchers appreciate the purity of quartz glass. It has a low thermal expansion coefficient, which provides stability during intense heating. A study highlights that quartz crucibles can withstand temperatures beyond 1000 degrees Celsius. This makes them indispensable for melting and holding materials like metals and ceramics. However, there are challenges. Some users may find the fragility of quartz glass a concern, especially during handling and transport.

Moreover, quartz glass crucibles can be expensive compared to alternatives. This raises questions about cost-effectiveness in different applications. Understanding these dynamics is crucial for businesses and laboratories. Addressing the balance between performance and cost remains a critical conversation in the industry. As the use of Quartz Glass Crucibles expands, ongoing research and innovation will drive future developments.

Quartz glass, known for its remarkable properties, is a type of glass made from silicon dioxide. This material is resistant to high temperatures and thermal shock. It boasts excellent transparency to a wide range of wavelengths, making it ideal for numerous applications. Its chemical durability ensures that it can handle corrosive substances without alteration. These qualities make quartz glass a popular choice in laboratories and industrial settings.

The production process of quartz glass involves melting high-purity silica sand at elevated temperatures. This careful procedure results in a glass with low impurities and high optical clarity. Despite its strengths, quartz glass can be brittle. When handling quartz glass crucibles, precision is crucial. Even minor cracks can lead to failure during high-temperature applications. Users must ensure proper storage to avoid accidental damage. The balance between utility and vulnerability requires constant diligence.

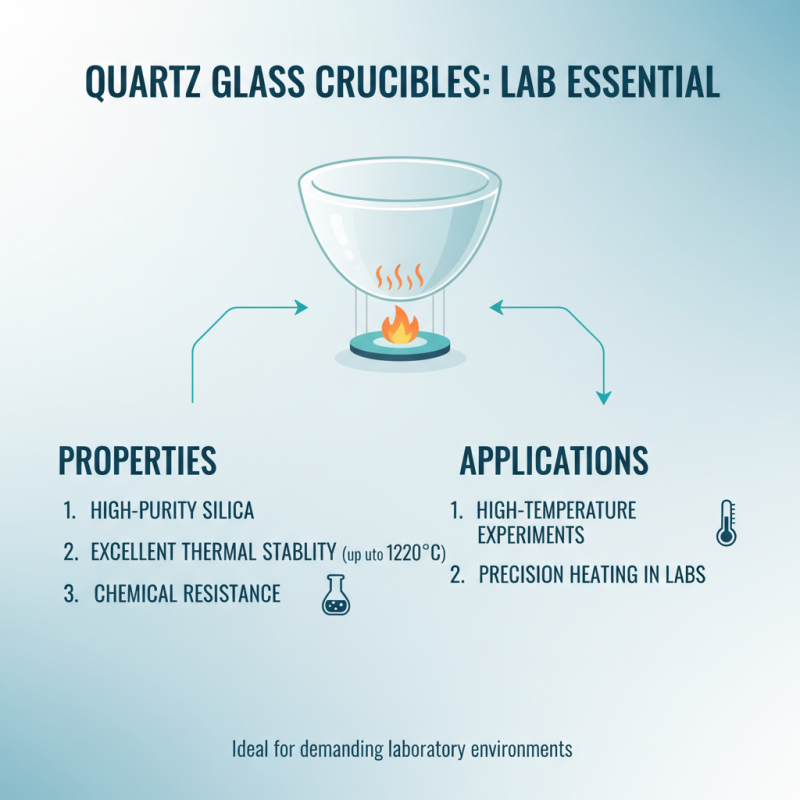

Quartz glass crucibles are vital in the field of high-temperature applications. They are primarily made from high-purity silica. The manufacturing process involves melting silica at extreme temperatures, around 1,700 °C. This ensures the crucible can withstand thermal stress and avoid contamination.

The production typically requires the use of high-quality raw materials. Industry data indicates that the use of synthetic quartz can increase the durability of the crucibles by up to 30%. During the forming process, precision is crucial. Even minor deviations can lead to structural weaknesses. Many producers prefer to use methods like flame fusion to enhance clarity and strength.

After forming, these crucibles undergo stringent quality checks. Inspectors look for imperfections or defects that may compromise functionality. It's essential to ensure that the final product can endure repeated thermal cycling. The need for continuous improvement is evident. Despite advancements in technology, issues like micro-cracks can still arise. These imperfections can affect performance and longevity, warranting further research and innovation in the manufacturing process.

Quartz glass crucibles are essential tools in many laboratories. They are made from high-purity silica, which offers excellent thermal stability and chemical resistance. This makes them ideal for high-temperature applications. In labs, you will often find quartz glass crucibles used in experiments that require precise heating.

Commonly, they serve in material synthesis and melting processes. Scientists use them to heat metals and other materials to extreme temperatures. They withstand harsh conditions without breaking down. Furthermore, quartz crucibles play a role in chemical analysis. Their inert nature prevents contamination of samples.

However, using quartz crucibles comes with challenges. They can be brittle if not handled carefully. Dropping them might lead to cracks that affect their usability. Striking the right balance between durability and performance is crucial. Despite these limitations, quartz glass crucibles remain favored in laboratory settings. They offer unmatched purity and can endure most chemical reactions without compromise.

Quartz glass crucibles are essential in various industries, particularly in high-temperature applications. Their ability to withstand extreme heat makes them ideal for processes like melting and crystallization. According to a recent industry report, quartz crucibles can tolerate temperatures exceeding 1,200°C. This property allows for effective use in laboratories and manufacturing facilities.

One significant advantage of quartz glass crucibles is their chemical resistance. Unlike other materials, quartz does not react with most chemicals. This stability reduces contamination risks in sensitive experiments. A study indicated that quartz crucibles have a lower leaching rate than alumina or ceramic alternatives. This feature is crucial for maintaining the integrity of high-purity materials.

Another noteworthy aspect is their thermal shock resistance. Quartz glass can handle rapid temperature changes without cracking, which is a common issue with other crucible materials. However, the production of quartz glass can lead to a higher cost. This might deter some users from adopting it. Yet, the longevity and reliability often justify the initial investment. Users should weigh these pros and cons when choosing materials for their specific applications.

Quartz glass crucibles are essential tools in various scientific and industrial applications. Proper maintenance is crucial for ensuring their longevity and functionality. These crucibles can withstand high temperatures but require specific care to avoid damage.

Cleaning these crucibles is paramount. After each use, allow them to cool down. Clean them with a soft cloth and avoid abrasive materials. Any scratches can lead to future cracking. Did you know that even minor impurities can affect results? Keep your work area tidy to prevent contamination.

Tip: Always inspect your crucibles for chips or cracks before use. Even small imperfections can become significant over time. Store them in a safe, padded container to minimize risk. This simple habit can extend their life and performance.

Remember, how you handle your crucibles matters. Avoid rapid temperature changes; it can cause thermal shock. If you notice any discoloration, it might indicate wear. Being attentive to these details can save you from costly replacements. Each step taken in care and maintenance reflects on your work’s accuracy.