Enhancing the Strength of Quartz is crucial for many projects. Whether you are working with countertops, flooring, or decorative elements, the durability of quartz directly impacts the outcome. Strength is not just about resistance to pressure; it’s also about how it withstands wear and tear over time.

Many people overlook simple strategies to boost the strength of quartz. For instance, choosing the right resin and ensuring proper curing can significantly improve the material's resilience. Understanding the specific needs of your project is equally important. Sometimes, it's easy to skip essential steps, leading to weaknesses in the final product.

It’s important to reflect on the craftsmanship involved. Quality control and regular testing can help identify potential flaws. Keeping an open mind about innovative techniques can also enhance strength. In our journey to improve the Strength of Quartz in our projects, we must embrace these tips to achieve superior results. Failure to do so can result in disappointing outcomes, which serve as a learning opportunity.

Quartz is a fascinating mineral. It’s the second most abundant mineral in the Earth's crust. This makes it a staple in many projects, from countertops to electronics. Its unique properties help in a wide range of applications. For instance, quartz is highly durable. It resists scratches and impacts well. However, it isn’t completely indestructible. Sometimes, it can chip or crack under extreme pressure.

Understanding quartz’s unique structure is crucial. It has a crystalline form that contributes to its strength. This specific arrangement affects hardness and resilience. However, handling quartz requires care. Not all quartz stones are equal. Variations in purity and processing can weaken its overall integrity. Also, the finished product can show imperfections. These flaws can be concerning for users. It's essential to choose quartz wisely, balancing aesthetics with functional strength.

Incorporating quartz into projects routinely comes with challenges. You must consider compatibility with adhesives and sealants. Some combinations may compromise quartz's performance. Testing these combinations is necessary to avoid future problems. Staying informed about advancements in quartz technology can also help. Sometimes, finding the right solution takes time and experimentation. Embracing these challenges can lead to better results in the long run.

When it comes to quartz, purity directly impacts its strength. High-purity quartz contains fewer impurities, which means better performance in various applications. Lower purity can weaken the structure. Impurities introduce flaws that can cause failures under stress. Therefore, sourcing high-quality quartz is crucial for any project.

One essential tip is to analyze the quartz before use. Test for impurities that may affect strength. Crystalline structure also matters. Ensure the quartz has a uniform pattern for optimal durability. Another way to enhance quartz strength is through proper preparation. This includes cleaning the quartz thoroughly to remove any contaminants.

Moreover, consider the environment in which quartz is used. Certain conditions could affect its integrity over time. Monitor exposure to chemicals or extreme temperatures. Sometimes, even small factors can lead to significant weaknesses. Being proactive in these areas will strengthen the overall effectiveness of your quartz projects.

Cutting and shaping quartz requires precision and the right tools. First, choose a diamond blade for clean cuts. This material is tough, and standard blades often struggle. Ensure proper water cooling during the cutting process. It prevents overheating and reduces the chance of cracking. A steady hand and a clear plan are crucial. Layout your design clearly before starting. Mistakes can be costly and hard to fix.

When shaping quartz, consider both the technique and safety. Always wear protective gear. Dust can be harmful, and shards can injure. Use a grinder with a diamond cup wheel for smoothing edges. This tool effectively removes imperfections while minimizing surface damage. Always keep the quartz wet for better results. It’s a common oversight that can lead to frustration and subpar results.

Sometimes, despite best efforts, the quartz may not come out as desired. It can be disheartening when a project doesn’t meet expectations. Reflection on these moments is essential. Analyze what went wrong. Was it the tool choice or the technique? Learning from these experiences will lead to better outcomes in the future. Embrace the imperfections; they often teach the most valuable lessons.

When working with quartz in your projects, enhancing its durability is key. One effective method is through proper sealing. A high-quality sealant can protect quartz from moisture and stains. It’s essential to choose a sealant designed for quartz to ensure maximum protection. Regular reapplication is crucial. Over time, sealants wear out and may need attention.

Another method focuses on the installation process. Uneven surfaces can lead to stress points. Ensuring a level surface during installation minimizes the chances of cracking. Always double-check measurements before cutting or placing quartz. Collaborate with skilled professionals when needed. Sometimes, a simple oversight can lead to significant issues later.

Additionally, consider environmental factors. Extreme temperature changes can impact the integrity of quartz. If your project is outdoors, think about protective coverings or shaded areas. Also, avoid placing hot objects directly on quartz surfaces. It’s a simple step but often overlooked. Each of these methods contributes to a more durable quartz installation, but they require attention to detail and proactive maintenance.

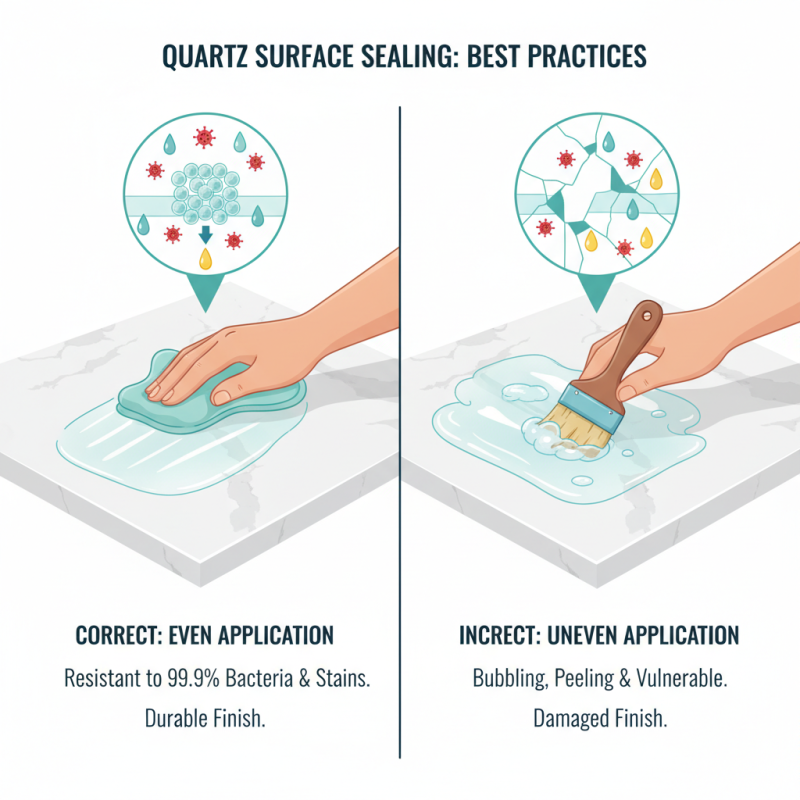

When it comes to finishing and sealing quartz surfaces, several best practices stand out. Proper sealing can significantly enhance durability, making quartz resistant to stains and bacteria. Industry reports indicate that a well-sealed quartz surface can resist over 99.9% of common household bacteria. However, it is crucial to apply the sealant evenly and in thin layers. Uneven application may lead to issues like bubbling or peeling over time.

Proper surface preparation is essential before sealing. Any dirt or grease left on the quartz can compromise adhesion. A clean, dry substrate allows the sealant to bond effectively. Studies show that quartz surfaces with meticulous prep work last 20-30% longer than those that are not properly maintained. Beyond sealing, regular cleaning is vital. Using a pH-balanced cleaner can help maintain the surface without causing damage. Harsh chemicals may warp or dull the finish, leading to premature wear.

Despite robust qualities, some challenges remain. Even durable quartz can chip or scratch if subjected to heavy impacts. Users may overlook minor nicks until they become significant. Regular inspections can mitigate these effects, allowing for timely repairs before small issues escalate. Understanding these nuances is crucial to maximizing the longevity of quartz surfaces in any project.