In the world of laboratory equipment, choosing the right materials is crucial. Quartz Glass Crucibles are known for their high-temperature resistance and chemical durability. According to a 2022 industry report, the demand for quartz glass products is increasing by 8% annually. This reflects a growing reliance on high-quality crucibles in scientific research.

Dr. Emily Johnson, a leading materials scientist, emphasizes, "Selecting the proper Quartz Glass Crucible can significantly impact experimental outcomes." Her expertise highlights the importance of making informed choices. The right crucible ensures accuracy in processes like melting, calcining, and sintering.

Despite their benefits, many laboratories overlook key factors in their selection. For example, the size, thermal shock resistance, and purity level of quartz must be considered. A misplaced focus can lead to compromised results. Many professionals still struggle with understanding these variations. The quest for the ideal Quartz Glass Crucible requires diligence and knowledge from all who use them.

Quartz glass crucibles play a vital role in laboratory settings. They are essential for high-temperature applications due to their excellent thermal resistance. Research indicates that quartz can withstand temperatures up to 1,200 degrees Celsius without deforming. This property makes them indispensable for processes such as melting, boiling, and incinerating samples.

In a recent industry report, it was highlighted that the demand for quartz glass crucibles is increasing by 5% annually. Labs rely on these crucibles for their chemical resistance and low contamination levels. However, not all quartz glass is created equal.

Some crucibles may contain impurities, which can affect experimental results. It’s essential to vet suppliers and ensure that the quartz used meets high purity standards.

While the benefits are clear, choosing the right crucible can be challenging. Many users overlook the importance of size and shape. A crucible that is too small might not handle the sample volume. Similarly, a poorly designed shape can lead to uneven heating. This aspect is often debated in the scientific community.

There's a tendency to overlook the subtle impacts on experimental outcomes, yet they can greatly affect data integrity. Making informed choices is crucial for reliable results.

When selecting quartz glass crucibles for laboratory use, several key factors must be considered. The thermal resistance of quartz glass is essential. It can withstand high temperatures, often exceeding 1,000 degrees Celsius. This makes it suitable for various applications including metal casting and chemical analysis. However, not all quartz glass is created equally. Variations in purity can influence its performance and durability.

Another important aspect is the crucible's chemical compatibility. Quartz crucibles generally resist acids and bases well, yet specific chemicals may affect their integrity. A study by the International Journal of Chemical Studies emphasizes the need for testing crucibles against anticipated chemicals. A mismatch can lead to heating failures or contamination of samples. Additionally, physical dimensions should align with experimental requirements. Dimensions that are too small can lead to spillage, while overly large crucibles may alter the reactions being studied.

Cost is also a crucial factor. While quality often comes at a higher price, budget constraints can limit options. Researchers frequently find themselves weighing performance against budget. It’s vital to consider long-term benefits over initial costs. A well-chosen quartz crucible can lead to more accurate results and eventual savings in material losses or product flaws. Balancing these factors ensures optimal laboratory performance and reliable outcomes.

When selecting quartz glass crucibles, understanding their types is crucial. There are different kinds suited for specific tasks. Some are ideal for high-temperature applications, while others are perfect for chemical reactions. Each type has its own benefits and limitations.

Consider the application. For instance, crucibles used in metallurgy must withstand extreme conditions. These can tolerate thermal shock and high melting points. On the other hand, those used in analytical chemistry may need a higher degree of purity. This is vital for accurate results.

When choosing a crucible, it's essential to evaluate thermal stability. Look for resistances to sudden changes in temperature. This affects the crucible's longevity. Always check compatibility with your materials. This ensures minimal reaction with the crucible. A poorly matched combination can lead to unreliable results or contamination.

Remember to assess the size and shape. The right dimensions can streamline your experiments. Oversized crucibles may waste energy; undersized ones can compromise safety. Keep these tips in mind while making your decision.

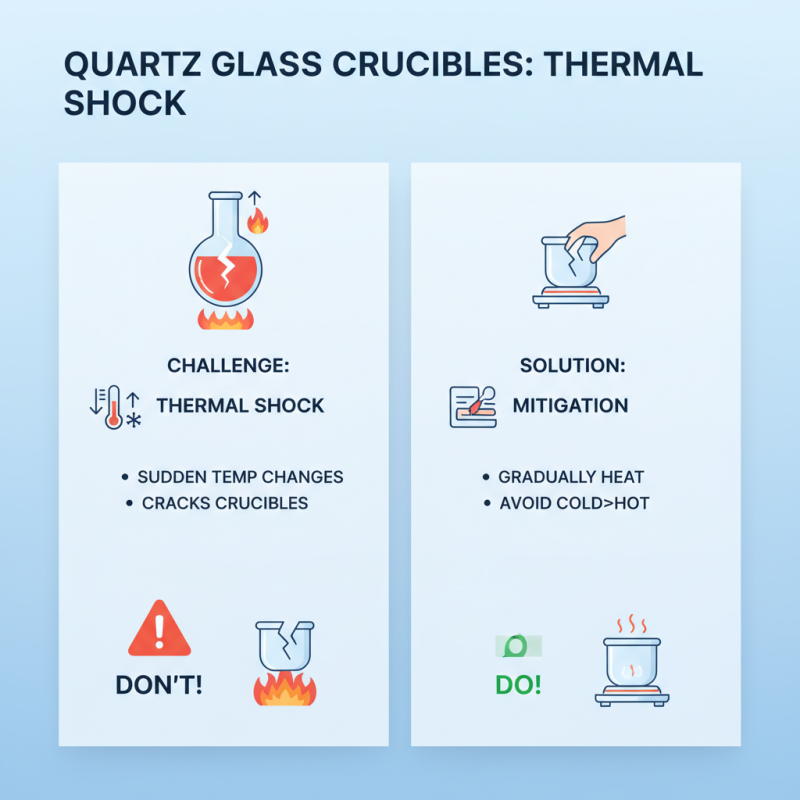

Proper handling and maintenance of quartz glass crucibles are crucial for their longevity. These crucibles are sensitive to thermal shock. Rapid temperature changes can cause cracks. Gradually heat them to prevent stress. Avoid placing cold crucibles in hot environments, as this can lead to catastrophic failure.

Cleaning is essential to maintain their clarity and performance. Use soft cloths and gentle cleaning agents. Hard brushes can scratch the surface. Remember that scratches can impact accuracy during experiments. Store crucibles in a safe and stable place. A secure environment prevents accidental drops and damages.

Regular inspections are key. Look for any signs of wear or damage before each use. Even minor cracks can lead to significant issues during testing. Make a habit of documenting your crucible's conditions. This reflection can help you improve your handling techniques over time. Emphasizing a careful approach can lead to more reliable results in your laboratory work.

Quartz glass crucibles are essential for many laboratory applications. However, they come with their own set of challenges. One common issue is thermal shock. Sudden temperature changes can crack crucibles. To mitigate this, gradually heat the crucible. Avoid placing a cold crucible directly into a hot environment.

Another problem is contamination. Residues from previous experiments can affect results. Ensure you clean crucibles thoroughly between uses. Using proper cleaning agents can help. Sometimes, even minor scratches can harbor contaminants. Regularly inspect for any signs of wear.

Handling quartz glass requires care. Breakage can occur if dropped. Use protective gear and handle with precision. Working with appropriate equipment reduces risks. Cross-contamination is another concern. Designate specific crucibles for certain materials to prevent this issue. Regular training for lab personnel can also enhance safe handling practices.