In the fast-paced world of manufacturing, efficiency is paramount. A crucial factor in maintaining this efficiency is the presence of a Chip Cleaning Tank. Reports indicate that up to 30% of production downtime can be attributed to inadequate chip removal processes. Chip buildup not only hinders machinery but also affects product quality.

The Chip Cleaning Tank provides an effective solution. It allows for the removal of metal chips and contaminants quickly. This process not only improves machine performance but also extends equipment lifespan. According to industry experts, companies utilizing these tanks report an average productivity increase of 20%.

However, the implementation of Chip Cleaning Tanks is not without challenges. Many manufacturers struggle to adapt existing systems. Regular maintenance of these tanks is essential to avoid operational inefficiencies. As the industry evolves, the need for efficient chip management becomes increasingly clear. Addressing these challenges is vital for staying competitive.

In modern manufacturing, chip cleaning tanks play a crucial role. These tanks efficiently remove metal chips and contaminants during machining processes. When cutting tools operate, chips accumulate, which can lead to reduced tool performance. If these chips are not removed properly, the quality of the finished product may suffer.

Chip cleaning tanks create a continuous cycle for debris removal. They allow for automatic cleaning, improving production speed. Without these systems, machines can become clogged, causing costly downtime. It’s easy to overlook their importance until a failure occurs. Manufacturing environments require constant attention to detail. A neglected chip cleaning system can lead to mishaps.

Proper maintenance of chip cleaning tanks is essential. Regular inspections help identify wear and tear. A dirty tank can negate its benefits. Employees must be trained to recognize signs of malfunction. However, this training is often overlooked. Inadequate knowledge leads to errors. Investing in education around maintenance is critical for ensuring efficiency in manufacturing.

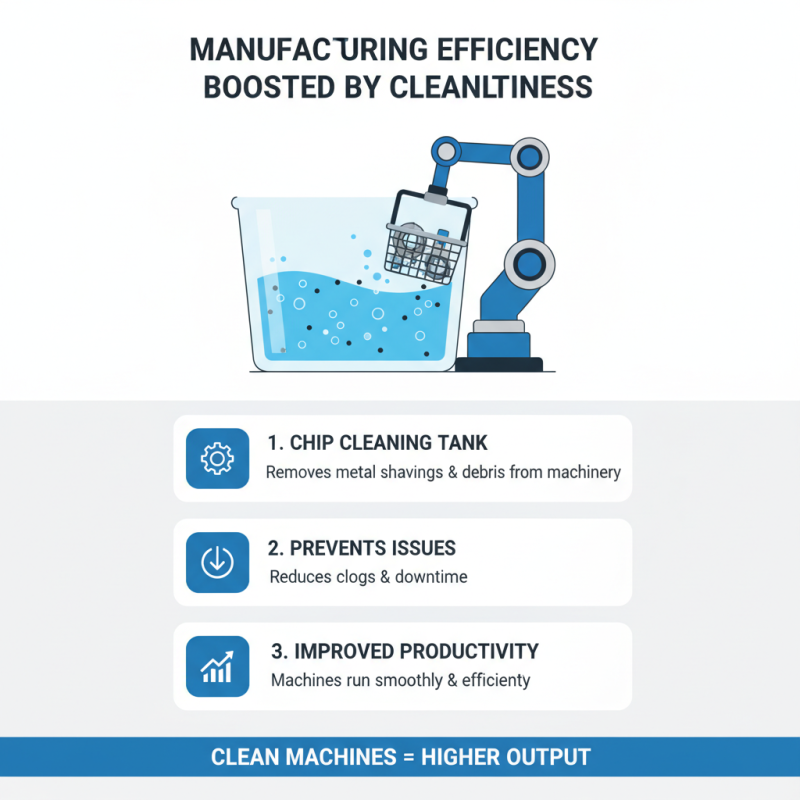

Manufacturing efficiency relies heavily on cleanliness. A chip cleaning tank plays a crucial role in this process. It helps remove metal shavings and debris from machinery. This prevents clogs and reduces downtime. When machines are clean, they run more smoothly. Efficiency improves, leading to higher productivity.

A chip cleaning tank also enhances product quality. Contaminants can affect the final output. By using a chip cleaning tank, companies maintain better standards. Workers spend less time on maintenance. They can focus on producing high-quality products instead. However, maintaining the tank itself might require attention. Ignoring regular cleaning can negate its benefits.

Investing in a chip cleaning tank does come with challenges. Setting it up takes time and resources. Workers need training to use it effectively. Some may resist change. But the long-term benefits often outweigh initial hurdles. An efficient manufacturing process relies on such tools for optimal performance.

Chip cleaning tanks play a crucial role in manufacturing processes. They are designed to remove metal chips, debris, and contaminants efficiently. This ensures that machines operate smoothly and maintain high levels of accuracy. A clean working environment reduces the risk of machine damage and increases productivity.

These tanks consist of several components. A filtration system captures chips during the cleaning process. Pumps help circulate the cleaning fluid, ensuring optimal coverage. Often, heaters are included to maintain fluid temperature, enhancing cleaning effectiveness. Inspecting these parts regularly is necessary, as wear can impact their functionality.

Selecting the right chip cleaning tank can be challenging. Manufacturers must consider size, capacity, and layout. Not all tanks suit every facility. Some companies find themselves repeatedly fixing issues, leading to increased downtime. Proper installation and maintenance routines are essential to avoid these pitfalls. Addressing these challenges proactively can pave the way for smoother operations.

| Component | Functionality | Importance in Manufacturing |

|---|---|---|

| Chip Separator | Removes metal chips from the coolant | Enhances coolant efficiency and tool longevity |

| Filtration System | Filters particulates from the coolant | Maintains fluid purity and improves machining precision |

| Recirculation Pump | Circulates cleaned coolant back to machines | Ensures constant coolant availability for manufacturing processes |

| Control Panel | Monitors and adjusts cleaning processes | Optimizes operational efficiency through automation |

| Tank Body | Holds the coolant and chips during cleaning | Provides the essential space for effective cleaning |

Maintaining a chip cleaning tank is crucial in manufacturing. Regular maintenance ensures efficiency and cleanliness. Studies show that improper cleaning can lead to a 20% drop in productivity. This makes it essential to establish a routine cleaning schedule.

Operators should inspect the tank weekly. Check for blockages and residue build-up. Neglecting these tasks may lead to increased wear on equipment. According to industry reports, using subpar cleaning methods can double the operational costs over time.

Collecting chip waste efficiently is key. It not only preserves the equipment but also enhances the overall environment. Poorly maintained tanks can cause safety hazards. Workers may face risks from slippery surfaces. Training staff is vital. They must understand how to operate the cleaning tank correctly and safely.

When it comes to efficient manufacturing, the role of a chip cleaning tank cannot be overstated. These tanks are designed to efficiently remove metal chips and debris from machining processes. They help maintain cleaner workspaces. However, are there better alternatives?

Comparing chip cleaning tanks to other solutions reveals essential insights. Some facilities opt for vacuum systems. While effective, they often require more frequent maintenance. Manual cleaning can result in inconsistent outcomes and longer downtime. A chip cleaning tank, in contrast, offers a streamlined approach. It automatically collects and filters chips, enhancing productivity. Yet, some might argue that they take up more floor space.

Maintenance is another point of contention. Chip cleaning tanks may require periodic servicing. If neglected, they can lead to messier working environments. In contrast, simpler systems may require less oversight but demand more manual labor. Balancing efficiency and maintenance remains a crucial consideration. While chip cleaning tanks offer many benefits, they are not without their challenges. Evaluating the specific needs of a facility can help determine the best solution.

This chart compares the efficiency of chip cleaning tanks with alternative solutions such as manual cleaning and filtration systems based on average time saved during manufacturing processes.