In the realm of advanced materials processing, the Quartz Reactor stands out for its unique capabilities. Industry expert Dr. Emily Tran states, "The efficiency of a Quartz Reactor can greatly enhance overall production quality." This sentiment rings true as manufacturers increasingly seek high-performance solutions.

Quartz Reactors are essential in various applications, notably in semiconductor fabrication. Their heat resistance and chemical stability make them ideal for demanding environments. However, not all models offer the same efficiency. Some units may fall short, failing to meet evolving industry standards.

Selecting the right Quartz Reactor model is crucial. Factors such as design, thermal management, and operational capabilities can significantly affect performance. A mismatch could lead to inefficiencies, impacting product quality and operational cost. Inspection and feedback from end-users often reveal important insights about each model's practical effectiveness.

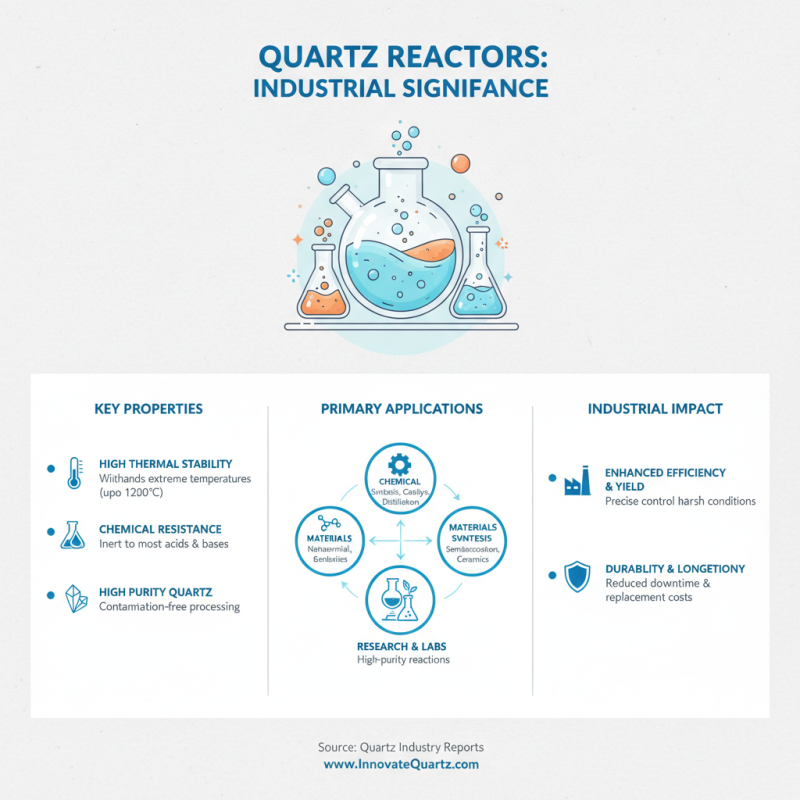

Quartz reactors are becoming more significant in various industries, particularly in chemical processes and materials synthesis. This technology utilizes high-purity quartz, which offers excellent thermal and chemical stability. Quartz reactors can withstand extreme conditions, making them suitable for numerous applications. Their ability to handle high temperatures and harsh chemicals makes them vital in laboratories and manufacturing.

Many professionals appreciate the efficiency of quartz reactors. They provide an even thermal distribution, which is essential for consistent results. The clarity of quartz allows for in-situ monitoring during reactions. However, setting up and maintaining these reactors can be tricky. Users must ensure proper sealing to avoid leaks. This can add complexity to processes that require precision.

Challenges still exist in utilizing quartz reactors. The material can be brittle, which demands careful handling. Additionally, some users might find it difficult to source compatible materials for piping and fittings. Reflecting on these challenges helps improve methodologies for better results. Advancing our understanding of quartz reactor technology will unlock its full potential.

When selecting quartz reactors for 2026, specific features stand out.

Efficiency is essential. High-quality materials enhance durability.

A well-designed heating system boosts performance.

Reports show that reactors with optimized thermal conductivity improve reaction rates by up to 25%.

Consider the ease of maintenance.

Reactors should allow for quick inspections and part replacements.

This reduces downtime, which can cost significant money.

Research indicates that facilities with efficient maintenance schedules save up to 15% in operational costs.

Tip: Regular training for operators increases efficiency.

A well-informed team can identify issues early.

Pay attention to the reactor's scalability.

As demand grows, the ability to increase capacity without major modifications is crucial.

Quartz reactors that offer modular designs are often preferable.

They adapt to changing needs without extensive investment.

Tip: Monitor energy consumption regularly.

This helps in identifying inefficiencies early on.

When considering quartz reactors for enhanced performance, several models stand out in 2026. These reactors are designed to optimize chemical reactions with minimal energy loss. They often feature improved thermal stability, ensuring consistency in temperature control. This stability is crucial for achieving reliable results in various applications.

Moreover, many advanced quartz reactors include user-friendly interfaces. These interfaces allow for easier monitoring of parameters. Some models also have customizable settings. This flexibility can lead to improved outcomes. However, it is essential to evaluate the specific needs of your processes before making a selection. Sometimes, finding the right model may involve trial and error.

It is worth noting that even the best reactors may have limitations. Some may struggle with certain materials, affecting the reaction rate. Users should be prepared for such challenges and learn from them. Reflecting on these experiences can lead to better future decisions. Embracing the learning curve can enhance operational efficiency.

This chart represents the performance and efficiency scores of different quartz reactor models based on several key metrics such as energy consumption, output efficiency, and durability ratings.

In 2026, the evolution of quartz reactors is remarkable.

These models focus on improving performance and energy efficiency. The market showcases diverse designs and features that aim to optimize chemical reactions.

Key factors for comparison include temperature control, reaction time, and energy consumption.

Some models excel in speed but compromise on stability. Others prioritize uniform heating but may lack in processing power.

It's essential to evaluate how each reactor aligns with specific needs.

A thorough analysis of user feedback reveals common issues like maintenance complexity and initial costs.

Each option carries strengths and weaknesses.

Some users feel overwhelmed by the specifications, complicating decision-making.

Finding the right balance between efficiency and usability is crucial.

A careful look at real-world applications helps reveal which models truly deliver.

The quartz reactor landscape is evolving rapidly. With advancements in material science, we see innovative designs that enhance performance. Changes are not just aesthetic; they impact efficiency. For instance, improved thermal stability allows for higher reaction rates. New configurations can maximize surface area, leading to better heat transfer.

Trends point toward more automation and smart controls. Such technology can optimize operations. Sensors integrated into reactors allow for real-time monitoring. This ensures better yield and reduces waste. However, the balance between complexity and usability must be considered. Over-complication can lead to operational errors.

Sustainability is a growing concern. Many designs now focus on reducing energy consumption. For example, incorporating energy-efficient heating elements is crucial. Some innovations aim to minimize the carbon footprint. Yet, the challenge remains: achieving efficiency without sacrificing performance. Companies must reflect on how far they can push these technologies while ensuring reliability.